The portable sandblaster machine is powered by compressed air to form a high-speed jet beam to blast material (shot glass beads, steel shot, steel sand, quartz sand, diamond sand, iron sand, sea sand) at high speed to the surface of the workpiece to be treated, laser cutting machine laser cutting equipment cast iron platform to change the mechanical properties of the outer surface of the workpiece, due to the abrasive impact on the surface of the workpiece and cutting, so that the surface of the workpiece by a certain cleanliness and different roughness, so that the mechanical properties of the surface of the workpiece is improved, thus improving the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, extending the durability of the coating film, but also conducive to the leveling and decoration of the paint, the surface of impurities, color and oxide layer removed, while roughening the surface of the medium, so that the role of the substrate surface residual stress and improve the surface hardness of the substrate.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Portable Sandblaster Machine Parameter:

| Model | YG-600 | YG-700 | YG-800 | YG-1000 |

| Volume(m3) | 0.26 | 0.3 | 0.6 | 1 |

| Height | 1150 | 1250 | 1700 | 2000 |

| Sand peening capacity | 5-10(m3/h) | 6-11(m3/h) | 10-12(m3/h) | 10-30(m3/h) |

| Air source configuration | 3(m2/min) | 3(m2/min) | 3.5(m2/min) | 4(m2/min) |

| Control System | Air control | Air control | Air control | Air control |

| Diameter | 600mm | 700mm | 800mm | 1000mm |

Work Principle of Portable Sandblaster Machine

Injection technology can be divided into three types according to the injection method: press-in, suction, and centrifugal. The press-in type injects compressed air and abrasives in the same container as they are mixed, which makes full use of the compressed air, and the airflow and sand flow can be easily adjusted to obtain an ideal mixing ratio (air and abrasives). High efficiency, low energy, abrasive consumption, versatility, and suitability for cleaning large areas are the most important features of the press-in type.

Sandblasting material: river sand, yellow sand, steel shot, steel shot, cut shot, brown corundum, corundum, quartz.

Characteristics of the Sandblasting Machine

- Simple operation: Ordinary workers can skillfully operate the machine after half an hour of training, and the advanced automatic control system can prevent workers from misoperation.

- High production efficiency: One freezing blasting machine can deal with an average amount of sandblasting equivalent to 50-80 skilled workers per day.

- High sandblasting precision: It can remove the very small and hidden fly edge, regardless of the shape of the product, high qualification rate, and stable sandblasting quality.

- Can remove the complex structure, any shape of small rubber and plastic alloy products, brittle plastic products, and magnesium alloy, zinc alloy, and aluminum alloy castings of the fringe.

- Does not damage the surface of the products, improves the quality of product appearance, and increases the service life of the product.

- Small footprint, only 10 square meters for a sandblasting machine and auxiliary equipment.

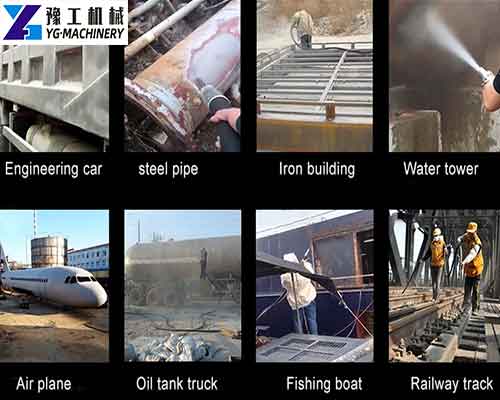

Application of Mini Sandblasting Machine for Sale in YG Machinery

- Clean the oxide skin and welding slag of heat treatment parts, welding parts, castings, forgings, etc., the cleaning quality can reach the Sa3 level.

- Clean micro burrs and surface residues of machined parts.

- It can be used as the pretreatment of the workpiece surface before coating or plating to obtain an active surface and improve the adhesion of the coating or plating layer.

- It can be used to improve the physical and mechanical properties of the surface of the workpiece, such as changing the surface stress state and improving the lubrication conditions of the mating parts.

- It is also suitable for the renovation of old machine parts.

Sandblaster Machine Manufacturer – YG Machinery

YG’s sandblasting machines have been sold to the United States, the Philippines, India, Pakistan, Indonesia, and many other countries, and they have always been the best-selling products of YG Machinery. At the same time, we also have shot blasting machines, sandblasting chambers, hanger shot blasting machines, dustless sandblasting machines, dry ice blasting machines, etc. Which are suitable for large-scale engineering projects. We also have equipment such as fog cannons, hydroseeding machines, mortar sprayers, shotcrete machines, putty spraying machines, cement foaming machines, gypsum spray plaster machines, micro excavators, mini concrete pumps, GRC machines, etc., which are suitable for different customers’ choices. Our equipment can be customized to meet the different needs of customers. Most of the equipment can be shipped within three days, and customers can quickly receive the goods. If you are interested, you can contact us now for more information!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()