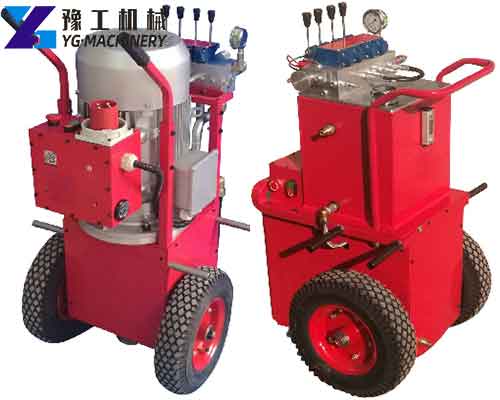

The hydraulic pile breaker is driven by hydraulic pressure and uses the power of the excavator or hydraulic station to break the pile. The combination of frequency converters can effectively remove the implanted pile head. This machine is currently the best-selling machine in YG Machinery. It has a wide range of applications and is of high quality and low price. At the same time, we also have other cutting machines, such as rock-splitting machines, diamond wire saw machines, concrete wall saw machines, etc. If you are interested, please contact us.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Composition of Hydraulic Pile Breaker:

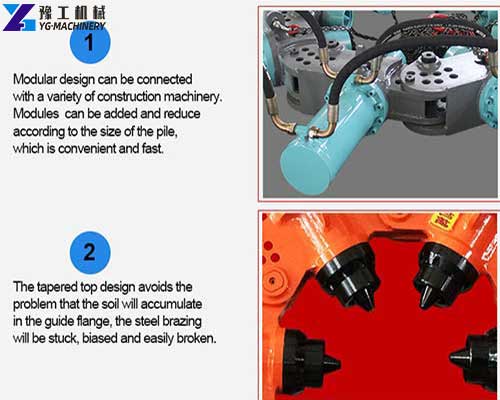

The hydraulic pile breaker is composed of modules, which are installed and disassembled according to the diameter of the pile removal head. It is installed at the front end of the excavator or crane and uses the power of the excavator or hydraulic station to break the pile, mainly to remove the solid cast-in-place pile and the solid prefabricated pile. According to site requirements, pipe piles may be removed.

Pile Breaker Parameter:

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.

Cylinder required |

20L/min | Machinery Tonnage | ≥20T | Location pin

Φ35 |

|||||||

| Max.

Cylinder Trip |

300mm | Chisel diameter | 110mm | Single

module weight |

335KG | ||||||||

| Max.

Cylinder Pressure |

300MPa | Max.

Hoist Capacity |

≤500mm | Single

module size |

1015*865*340mm | ||||||||

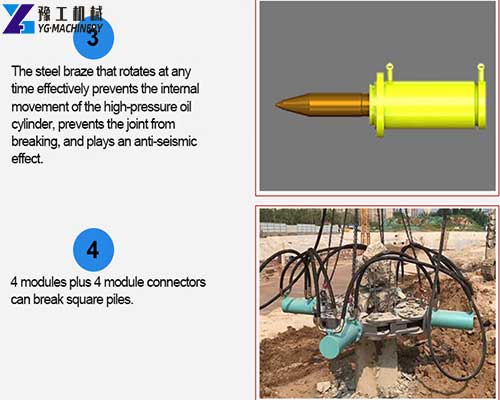

Hydraulic Concrete Pile Cutter Working Principle:

The pile breaker provides pressure to multiple oil cylinders of the pile-cutting machine through the power source, and the oil cylinder directly drives the drill rod, and at the same time squeezes the pile body to cut off the pile head. During the construction of the concrete pile-cutting machine, the operation is simple, high efficiency, low noise, and low cost, which is suitable for the construction of pile groups. The pile breaker adopts a highly modular combination, and the modules are connected through the pin shaft. The pile heads with a diameter within a certain range can be cut off by combining the number of different modules.

Concrete Pile Cutting Machine Application Range:

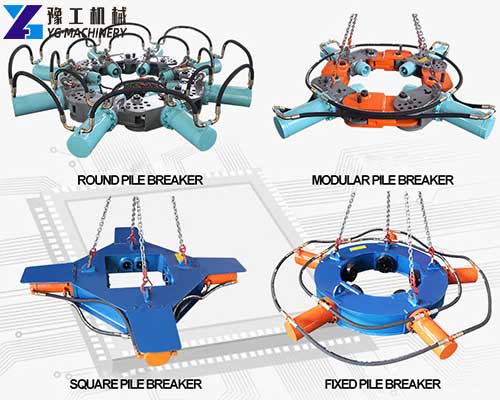

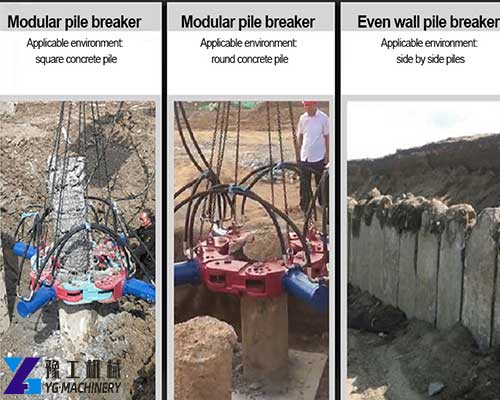

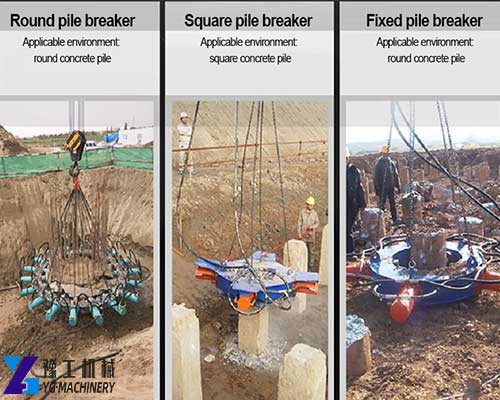

Hydraulic pile breaker: such as cast-in-place pile, prefabricated pile, etc. From the shape of the pile head, it can be divided into a round pile breaker and a square pile driver. The pile-cutting machine is widely used in high-speed railway bridges and pile foundation engineering of civil construction. The general circular pile cutter is suitable for pile diameters of 250 mm-2500 mm; the square pile cutter is suitable for pile side lengths of 300-650mm, which can meet all kinds of Requirements for large-scale foundation construction.

Product Advantages and Applications:

- Hydraulic pile breaker to achieve high efficiency and low noise pile cutting.

- Modularization, through the combination of different numbers of modules, to achieve the cutting of different diameter pile heads.

- High-cost performance and low operating costs.

- The pile-breaking operation is simple, requires no professional skills, and is relatively safe.

- The pile breaker can be connected with a variety of construction machinery to truly achieve the universality and economy of the product. Can be hung on the excavator, crane, telescopic boom, and other construction machinery.

- The design of a long life brings benefits to customers.

Operation Steps of Hydraulic Pile Cutting Machine:

- Suspend the installed hydraulic pile breaker at the front end of the excavator or crane, and connect the pipeline of the excavator or the pipeline of the hydraulic station.

- Enter the construction site and put the hydraulic pile breaker on the pile head to be removed.

- Using the power of the excavator or the power of the hydraulic station to break the pile.

- Move the hydraulic pile breaker 30-50cm down to continue pile breaking.

- Repeat steps 2-3 until the pile head is removed.

- Clean up broken piles.

Pile Breaker Manufacturer – YG Machinery

Recently, the pile cutter machine of YG Machinery has been very hot. Customers are calling and sending emails to ask about the pile cutter machine. Our machine works very efficiently and the noise is very low. Can be connected with a variety of machinery, high versatility. Of course, we also have rock splitters, crawler wire saws, hydraulic wall saws, electric wall saws, firewood splitter machines, excavator drum cutters, hydraulic breaker machines, excavator crusher buckets, excavator hydraulic shears, excavator rock saws, mobile crushers, excavator drill&splitting machines, etc. It can be used for cutting different projects and different objects. If you are interested, please contact us, and we will reply as soon as possible.

The convenient transportation network, advanced business concept, and perfect management system ensure the quality and rapid and healthy development of our company’s products. Our products can be customized according to the requirements of customers, and meet your needs. We can ship as soon as possible, the machine has a long life and good quality, so it must be your first choice.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

![]()