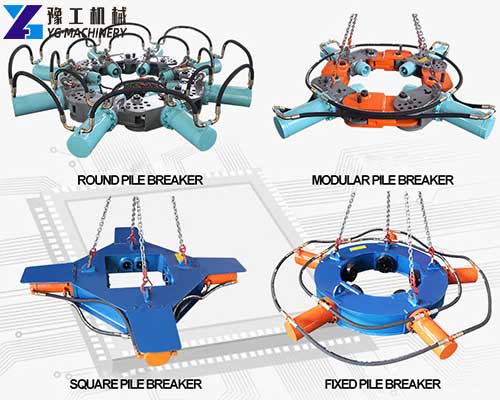

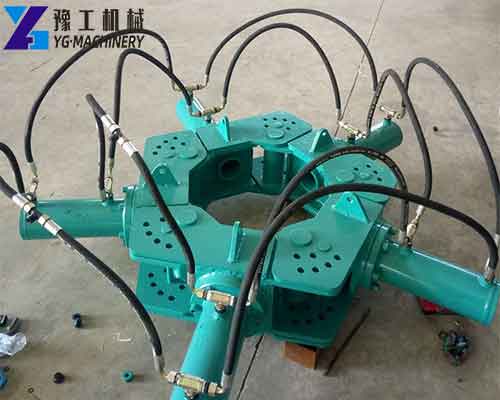

The hydraulic concrete pile cutter is currently the world’s most advanced equipment for removing pile heads. It uses multiple hydraulic cylinders to squeeze the pile body and simultaneously squeeze from different points on the same end surface to cut off the working principle of the pile head. It is simple, efficient, and environmentally friendly. The concrete pile cutter machine, also known as a hydraulic pile breaker, vividly shows its working process: in the process of high-speed rail, highway, and building construction, to better meet the foundation pile and the ground concrete structure, the general height of the foundation pile must be extended 1-2 meters above the ground, the function of the pile cutter is to cut off the pile head concrete that protrudes from the ground while retaining the reinforced part. In addition, YG Machinery also has concrete wall saws, hydraulic rock splitters, excavator rock splitters, wire saw machines, excavator hydraulic shears, mini spider cranes, excavator drum cutters, firewood splitter machines, hydraulic breaker machines, horizontal band saw machines, mobile crushers, etc. Contact us now to know more about cutting machinery.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Concrete Pile Cutter Machine Parameter:

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.

Cylinder required |

20L/min | Machinery Tonnage | ≥20T | Location pin

Φ35 |

|||||||

| Max.

Cylinder Trip |

300mm | Chisel diameter | 110mm | Single

module weight |

335KG | ||||||||

| Max.

Cylinder Pressure |

300MPa | Max.

Hoist Capacity |

≤500mm | Single

module size |

1015*865*340mm | ||||||||

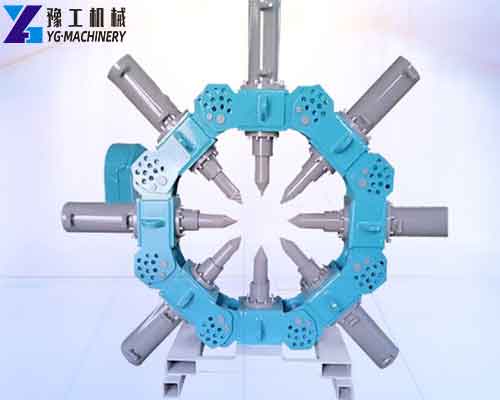

The Composition of the Pile Breaking Machine:

The hydraulic pile breaker is mainly composed of two parts: a power source and a working device. The working device is composed of multiple hydraulic cylinders of the same type to form a crusher with different diameters to meet the requirements of pile-breaking heads of various diameters. The piston is made of alloy steel, which can meet the crushing requirements of various grades of concrete. The power source can be a fixed pump station or other movable construction machinery equipment.

Working Principle:

The pile breaker provides pressure to multiple cylinders of the pile cutter through a power source. The cylinders directly drive the drill rod and simultaneously squeeze the pile body to cut off the pile head. During the construction of the pile-breaking machine, the operation is simple, high efficiency, low noise, and low cost, and it is suitable for pile group construction projects. The pile breaker adopts a highly modular combination, and the modules are connected by pin shafts, and the pile heads within a certain range of diameter can be cut through the combination of different modules.

Product Advantages and Applications:

- The hydraulic pile-breaking machine realizes high efficiency and low noise pile cutting.

- Modularization, through the combination of different numbers of modules, the pile heads of different diameters can be cut.

- High-cost performance, low operating cost, and cost performance are completely close to foreign products.

- The pile-breaking operation is simple, does not require professional skills, and the operation is quite safe.

- The pile breaker can be connected with a variety of construction machinery to truly realize the versatility and economy of the product. Can be hung on excavators, cranes, telescopic booms, and other construction machinery.

- Long-life design brings benefits to customers.

Instructions for Concrete Pile Cutter Machine:

Construction process: hydraulic module assembly → power system connection → pile breaking → repeated pile breaking → broken pile cleaning → manual repair.

- Hydraulic module assembly: According to the diameter of the pile head on site, assemble the corresponding number of hydraulic modules;

- Power system connection: Hang the installed hydraulic pile cutter on the front end of the excavator (or the front end of the crane), and connect it to the excavator hydraulic system (or an external hydraulic station) through a hydraulic pipe;

- Pile breaking: put the hydraulic pile cutter on the pile head that needs to be broken, and use the power of the excavator (or hydraulic station) to break the pile;

- Repeated pile breaking: move the hydraulic pile cutter down 300mm~500mm, continue breaking the pile, and repeat the action until the pile head is broken;

- Cleaning up broken piles: clean up the broken piles;

- Manual repair: manual repair to the design elevation.

Concrete Pile Cutter Manufacturer – YG Machinery Factory Price

With the continuous development of the pile-breaking industry, pile-breaking technology is constantly updated and replaced, from manual to mechanical, and the speed is improving step by step. Looking at the major brands of pile-breaking machine manufacturers at home and abroad, although the appearance is similar, their performance is very different, and this greatly affects the pile-breaking speed of the pile-breaking machine. YG pile breaker machine is high quality and factory price. In addition, we also have other equipment, such as wet tissue machines, tissue-making machines, napkin-making machines, A4 paper-making machines, paper cup-making machines, paper bowl-making machines, paper dish-making machines, paper straw-making machines, paper carton-erecting machines, paper tea cup printing machines, paper bag making machines, egg tray making machines, sanitary napkin making machines, etc. Want to know more details? Contact us now!【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800