A rebar straightening and cutting machine is a kind of steel processing equipment that is mainly used to straighten and cut various types of steel reinforcement materials, such as plain carbon steel, hot-rolled round steel, screw steel, and cold-rolled steel bars. The steel bar straightening and cutting machine can be widely used in various fields, such as highways, expressways, railways, high-speed railways, passenger dedicated lines, bridges, pile foundations, building construction, nuclear power plant project construction, standardized construction, steel bar processing plants, and some other industries. So if you are looking for a machine that can make the steel bar straight and cut it to the length you need at the same time, the rebar straightening and cutting machine will meet your requirements. Also, we have steel bar cutting machines, thread rolling machines, rebar bending machines, steel hoop bending machines, stirrup bending machines, chain link fence machines, and beam bending machines. Contact us.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Technical Parameters of Rebar Straightening And Cutting Machine

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

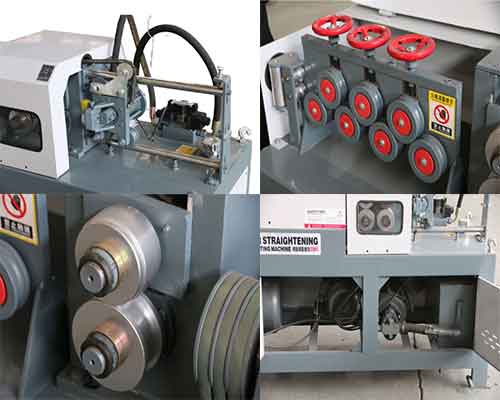

Automatic Rebar Straightening And Cutting Machine

The wire straightening and cutting machine for sale in YG Machinery has a high degree of automation and traction speed, which can make engineering easier and more efficient. In addition, our machine is capable of adjusting high and low speeds according to your needs. The machine can process steel bars with a diameter of 4-14mm.

Performance Advantages of Steel Bar Straightening Cutting Machine

- Intelligent control system. This machine is controlled by PLC which makes it simple and easy to straighten and cut automatically.

- High precision of ruler. The length error of the steel bar after cutting is less than or more than 0.5 to 1cm.

- Wide application. The diameter range of steel bars that can be machined is from 4mm to 16mm.

- High efficiency. The wire-pulling speed can reach 50m per minute.

- Simple operation, smooth operation, low fault rate, and convenient maintenance.

- Long service life. The straightening system adopts the design of a hyperbolic skew roll and is equipped with an alloy straightening wheel to reduce wear. The rebar doesn’t scratch after straightening and the strength loss is small. All the features make the service life of the machine long.

- Accurate cutting, no waste. Our machine adopts the hydraulic cutting machine, which can not only save tool loss but also fundamentally eliminate the phenomenon of continuous cutting. Thus the short broken steel bar is effectively reduced.

- Low noise and environmental protection.

- Electronic digital ruler. Multiple batches of input length and quantity at the same time, computer memory storage, which makes it more efficient and convenient.

- The speed can be adjusted arbitrarily, cutting a short steel bar at low speed and a long rebar at high speed.

The Working Principle of Rebar Straightening And Cutting Machine

The Straightening mechanism of the machine is mainly composed of a straightening roll, a straightening press, and the bearings at both ends of the machine. It is powered by an electric motor mounted on the lower part of the frame and the triangular belt drives the aligning shaft to rotate at high speed. The feed structure is composed of two pressure wheels running simultaneously.

First, the engine accelerates through the belt drive, which makes the straightening drum rotate at high speed. The steel bar passing through the straightening drum is straightened and the rust on the rebar surface is removed by straightening mode. Second, the motor passes through another pair of reduction belt drive and gear reduction boxes, which can drive the two conveying rollers to pull the reinforcing bar forward in one hand and drive the crank wheel to make the hammer move up and down at the other hand. When the steel bar is adjusted to the predetermined length, the hammerhead hammers the tool holder, cutting off the steel bar. When the steel bar falls into the material rack, the tool stand returns to the original position due to the spring action and completes the straightening and cutting.

How to Use The Steel Bar Straightening And Cutting Machine?

- Set the length and quantity of steel bars you want to process. Input the length and quantity of all batches that are up to 20 batches.

- After the setting is completed, place the steel bar that needs to be straightened, press the ‘cancel’ button to select the batch, then press the ‘run’ button. The machine can automatically produce the rebar according to the set length and quantity. After each batch is completed, the audible and visual alarm will last for 15 seconds. Then it will automatically run the next batch of steel bars. Of course, you can press the ‘stop’ button to stop production.

- Treatment when steel bars are entangled. Press the ‘run’ button and cut the rebar of the winding part.

- Handle the end of the steel bar. When the steel bar is processed to the end, press the ‘No Cut Off’ button, and the alarm light flashes once in three seconds this time. Clip the steel bar with the shear line at the outlet, and press the ‘run’ button to make the steel bar straight but not cut off. Then stop the machine and press the ‘No Cut Off’ button, if the straightening and cutting function display is back to normal, put the rebars and continue to produce.

- If the length is wrong, operators correct it easily. In the normal process of steel bars output, if you measure the average size of the steel bars input is different from the length you set, you can correct this with the ‘length+’ or ‘length-’ buttons. However, it should be noted that you need to press the ‘confirmation’ button, and the length correction work must be carried out in the state the machine is shut down. In addition, it also needs that the number of batches of steel bars isn’t completed.

Rebar Straightening And Cutting Machine Manufacturers – YG Machinery

Henan YG Machinery is a large machinery manufacturer specializing in research and development, production, and sales of all kinds of steel bar and pipe processing machinery, such as threaded rebar couplers, rebar upsetting machines, pipe shrinking machines, auto pipe bending machines, reinforced cage winding machines, automatic tapping machines, rebar de-rusting machines, hydraulic punch and shear machines, hydraulic thread rolling machines, as well as paper cup machines, double wall paper cup machines, roll die cutting machines, paper cup printing machines, paper bowl machines, folder gluer machines, etc. So if you have any need for this machinery, please feel free to contact me for a quotation. We guarantee we will provide you with top machinery at a competitive price.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800