The thread rolling machine is a multi-functional cold extrusion-forming machine tool. It can be used in conjunction with the rebar upsetting machine. The rebar threading machine can process the workpiece in the cold state under the rolling pressure range, such as threading, straight graining, and twill rolling; straight teeth, helical teeth, and diagonal splines rolling of gears; straightening, reduction, rolling, and various forming rolls. The thread rolling machine has a safe and reliable electric and hydraulic execution and control system that allows each duty cycle to be selected in manual, semi-automatic, and automatic modes. The rebar threading machine process is an advanced non-cutting process, which can effectively improve the internal and surface quality of the workpiece, and the radial compressive stress generated during processing can significantly improve the fatigue strength and torsional strength of the workpiece. The ideal process for energy saving and low consumption.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Rebar Thread Rolling Machine Parameter:

|

Model |

YGS-40 |

YGT-40 |

YGA-40 |

|

Processing diameter range |

16-40mm |

||

|

Thread rolling length |

0-80mm |

0-80mm |

0-100mm |

|

Power voltage |

4kw/380v 50hz |

4kw/380v 50hz |

7.5kw/380v 50hz |

|

Working efficiency |

15s/forming |

8s/forming |

One-touch auto forming |

|

Machine weight |

320kg |

350kg |

400kg |

|

Machine size |

115*50*106cm |

110*60*130cm |

126*70*106cm |

|

Type |

Standard type |

Upgrade type |

Full automatic type |

Application of Hydraulic Thread Rolling Machine:

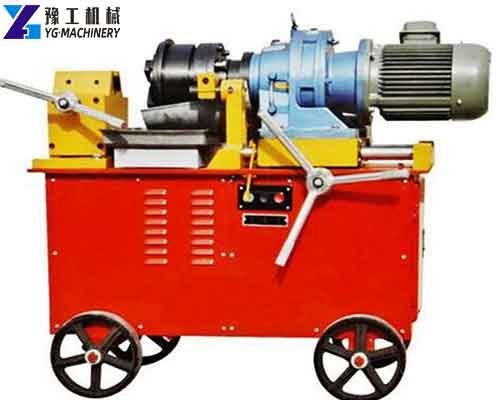

The steel bar rolling straight thread connection technology is suitable for industrial and civil buildings. It is required to give full play to the joint construction of the strong, oblique, and horizontal steel bars of important parts of the structure of steel strength and flexibility. The process is simple and quick, can be prefabricated, has no open fire operation, does not pollute the environment, has no hidden dangers of explosion, is safe and reliable, can be constructed all day, and saves a lot of steel and energy. Connect the reinforcing bars only with a wrench and each reinforcing bar joint for about one minute. The construction period of the structure was shortened and the industrialized civilized construction was realized. The steel thread rolling machine has a novel design, advanced technology, light, and flexibility. The operation is simple, the degree of automation is high, and the rib-ribbed rolling straight thread is formed at one time. The thread type has good quality and high precision. It has the same length as the straight thread of the same specification, and the connected steel head has no complete thread exposed. In addition, we also have hydraulic rebar threading machines, rebar straightening and cutting machines, rebar bending machines, steel hoop bending machines, beam bending machines, rebar de-rusting machines, punching and shearing machines, stirrup bending machines, chain link fence machines, etc. Contact us to know more.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

YG-40 Thread Rolling Machine for Sale

The Use:

YG-40 type thread rolling machine is mainly used for the construction of ribbed steel bar rolling straight thread head, which is the key equipment to realize the straight thread connection of steel bar. HRB335 and HRB 400 grade ribbed bars with a diameter of 16-40mm can be machined.

The Characteristic:

- YG-40 type steel straight thread rolling machine can be used for stripping and rolling thread simultaneously. The processing teeth are full and the dimensional accuracy is high.

- It can process the positive thread and the reverse thread.

- This machine is simple in operation, compact in structure, reliable in operation, and has a unique automatic opening and closing mechanism for the tool.

The Structure:

YG-40F straight thread rolling machine consists of a body, clamping clamp, sliding rod, sliding plate, cycloidal pinwheel reducer, stripping rib rolling head, feeding mechanism, automatic opening and closing mechanism, stroke limit mechanism, automatic return car mechanism, cooling mechanism, electrical control box, control system, and other components.

Equipment Safety Operation Precautions:

★ Warning: Power must be cut off during automatic model adjustment!

The following safety precautions should be taken into account during the use of the steel stripping rib rolling machine:

- The construction personnel must carry out technical training, and they can be certified to work after passing the examination.

- The equipment power supply must have a leakage protection device; the machine must have reliable grounding protection to prevent electric leakage and injury; the equipment should be cut off after the equipment is deactivated.

- After the steel bar is clamped on the vise, the steel bar must be clamped tightly. When processing the iron-bearing steel bars, it is strictly forbidden to stand at the iron-bearing place to prevent people from being hit because the steel bars are not clamped. If the steel bars are loose during processing, stop immediately, and clamp the steel bars again. Do not hold the steel bar by hand when the steel bar is rotating. Do not wear gloves for the operation.

- When the rolling head is rolled to the front limit, the power should be cut off immediately without stopping the machine. Do not use your hand to prevent the rolling head from rotating.

- The rolling head should not touch any rotating parts during the running process, such as the rolling head, expanding knife contact, etc.

- Equipment maintenance must be carried out by special personnel, and repairs and modifications must not be carried out in private.

- The device must not touch any charged device after turning on the power to prevent electric shock. Do not allow conductive substances such as water to enter the electrical box.

- The equipment should be stable when moving, loading, and unloading, so as not to tip over and hurt people.