The steel bar straightening and cutting machine is a kind of steel bar processing equipment, which is mainly used for the straightening and cutting of steel bars, also called rebar straightening and cutting machines. This product integrates straightening and cutting into one, which greatly improves work efficiency and reduces manual labor. This machine is a good choice for the steel processing industry. In addition, YG Machinery also has rebar upsetting machines, steel bar cutting machines, rebar threading machines, rebar bending machines, steel bar de-rusting machines, steel bar cold extrusion machines, rebar couplers, pipe shrinking machines, and so on. Please feel free to contact us for more details.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Technical Parameters of Rebar Straightening And Cutting Machine:

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

The Working Principle of the Steel Bar Straightening and Cutting Machine:

Input the quantity of sheared bar on the microcomputer controller, and set the installation position of the length control contacts on the stripper groove plate according to the sheared length of the bar. The motor drives the straightening frame with the straightening pulley to rotate at high speed. At the same time, when the straightened bar is stretched to the set length, it touches the length control contacts at the pre-set length distance and connects to the automatic cutting control circuit of the microcomputer controller, which controls the automatic bar cutting mechanism and automatically stripping mechanism by pulling the electromagnet to realize the synchronized automatic cutting and stripping of the bar.

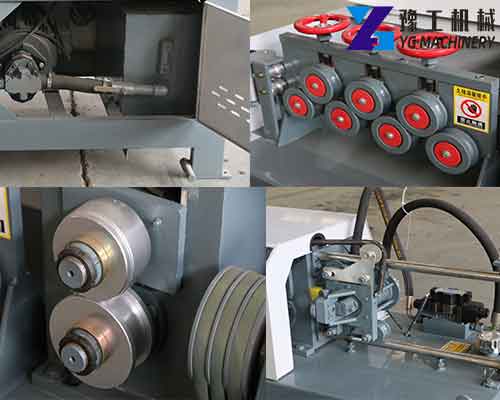

6 Advantages and Details of the Machine:

- Microcomputer control, automatic straightening, automatic length, automatically cut off.

- “Fool” type of operation, who can use it that understand the “123”.

- Multiple batches simultaneously enter the length and number of computer memory.

- Hydraulic cut, more accurate, quieter.

- An area of small, easy-to-install mobile.

- Stable operation, low failure rate, easy maintenance, and cheap accessories.

Maintenance and Safety:

- Ensure that there is enough lubricating oil in the transmission box and replace it regularly.

- Both ends of the straightening cylinder are lubricated with dry oil, and the oil is added regularly. The hammerhead slide block should be refueled once per shift, and the square knife table guide rail surface should be refueled once per shift.

- Add dry oil to the upper hole of the pan material rack regularly, and add lubricating oil to the supporting block of the material rack every shift.

- Check the status of the hammerhead and cutter regularly, and replace them if they are damaged.

- Do not open the belt cover and straighten the barrel cover to prevent danger.

- The electrical part of the machine must be equipped with a grounding wire.

Why Choose Rebar Straightening And Cutting Machine in Construction Projects?

In construction engineering, the emergence of the steel bar straightening and cutting machine reduces the labor intensity of workers and realizes intelligent straightening and cutting. It also speeds up the process of construction work. It is a very frequently used equipment on the construction site. Reinforcing steel is one of the indispensable materials in construction projects. In actual transportation, most of the steel rebars are rolled up for the convenience of transportation, and the equipment needs to be straightened during use.

It is mainly used for standard parts processing, cutting steel bars to length in housing construction, bridges, tunnels, power stations, large-scale water conservancies, and other projects. Compared with other cutting equipment, the steel bar cutting machine has the characteristics of being lightweight, less energy consumption, reliable work, and high efficiency. Therefore, in recent years, it has been gradually adopted by mechanical processing and has played an important role in various fields of national economic construction. 【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

![]()