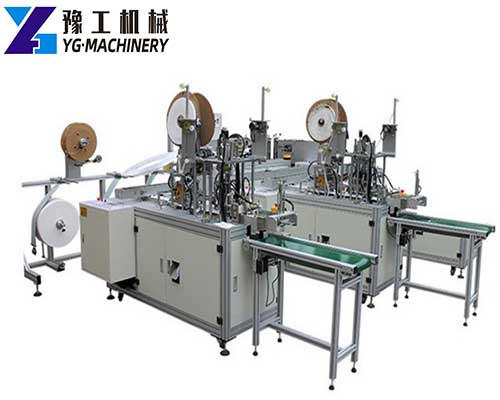

YG company independently developed the “non-woven mask slice forming machine”, which is a special machine for producing double-layer or multi-layer non-woven mask sheets. Built-in time, total output, the output of the day, set number of automatic alarms and shutdown, digital sound adjustment of filming speed, mask output from the conveyor belt, the speed is adjustable, the output is neat, gear reduction with brake function, extremely noisy The mask is formed by ultrasonic welding, which has excellent performance, high-speed filming, the thickness of the mask can be adjusted within a certain range, and the length of the nose bridge can be adjusted arbitrarily.

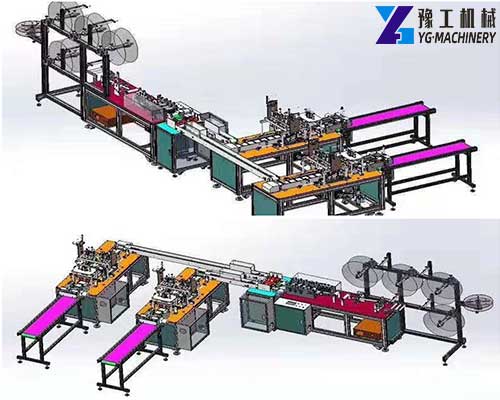

The film machine is part of the face mask making machine. We have an N95 machine and a flat mask machine. They are mask models developed by YG Machinery. The device includes a mask-forming machine and two semi-automatic double ear straps. One earloop welding machine, nose bridge equipment, and one ultrasonic edge banding machine. It includes a full set of the assembly line equipment, including mask forming, mask blanking, mask cutting, ear strap welding, upper nose bridge, printing, breathing valve welding, etc. Among them, automatic ultrasonic equipment is used to produce masks. One machine can complete the cutting, which greatly improves production efficiency, and the operation is simple and convenient. In addition, we also have meltblown production lines, meltblown nonwoven fabrics, wet tissue machines, rewinding machines, tissue making machines, disposable cup making machines, paper bag making machines, etc. If you are interested, please contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

The Principle of Mask Slice Forming Machine:

A mask filming machine is a machine that mainly uses the principle of ultrasonic welding and automatic edge banding to complete the welding and punching process of the edge of the cup mask. The mask film machine adopts a PLC control system, touch screen setting, simple and convenient operation, can be used by a single person, only needs workers to unload and take materials, can greatly save labor, uses automated production, can use 1~4 The layer of PP spunbond nonwoven fabric activated carbon and filter material, the entire machine from the raw material into the nose line insertion, edge banding, cutting finished products are all one-line automated operations.

| Voltage | 220V / 50Hz,60Hz |

| Production Speed | 100 – 130 PCS / Min |

| Stock | Yes |

| Quality | Video Online Check |

| Weight | 300 Kg |

| Specification | 6000x2000x1800 |

| Installation | Free Guide |

| Warranty | 3 Years |

| Transport Package | Wooden |

| Origin | China |

Machine Characteristics:

- The roll material non-woven fabric enters and is automatically made into a mask body.

- Adopt stainless steel, chrome-plated parts that are assembled firmly and cleanly.

- The production speed is fast, it can reach more than 150 pieces per minute.

- The folding position and size can be adjusted as needed.

- The 2-4 layer mask body can be produced, and it is widely used.

- High stability and excellent performance.

Application of Mask Film Machine:

The finished mask body produced by the mask film machine is not a final consumer product, but only a semi-finished product. It needs to be further processed to meet people’s daily needs. Therefore, the mask body machine is only the beginning of the related mask production process. It is only used in the production of inner ear band masks, outer ear band masks, and bandage masks. For example, the production of bandage masks is to place the finished mask body on the machine conveyor, pass through the pull tube, and then use After the ultrasonic flower wheel is pressed and welded, the strap is cut to output the finished product. Only one person needs to place the mask body on the conveyor belt of the machine, and the rest of the subsequent work is completed automatically. For example, the production process of the strap mask machine is as follows: The mask body piece is fed in the strap is welded-the strap is cut off. The production process of the remaining masks, such as the outer band and inner earband masks, is about the same as above.

Slice Forming Machine Configuration :

This machine is a machine for the fully automatic production of finished masks. Fuse the mask with ultrasonic fusion. From the production of the mask body to the welding earband, it is fully automated and completed at one time without any manual operation.

1. The direction and style of ear straps can be equipped according to customer requirements.

2. High output, can produce 1-4 layer masks according to customer requirements.

3. The folding position of the mask can be adjusted.

4. Feeding system:

- The whole machine adopts an aluminum alloy structure, which is beautiful and firm and does not rust;

- The automatic feeding system, and the setting of the tension wheel, adjust the tension of the cloth width, to effectively ensure the appearance and smoothness of the finished product.

5. Control system:

- Computer process control, a photoelectric detection device, high stability, and low failure rate;

- Automatic counting, which can accurately control production efficiency and production schedule;

- Frequency conversion control, users can adjust the production speed according to actual needs; 4. Rotating the control box, the user can adjust the operation direction according to actual needs.

6. Discharging system:

- Fully automatic waste recycling device, which is convenient and efficient for waste recycling;

- Automatic classification of finished products and waste, reducing labor intensity.

![]()