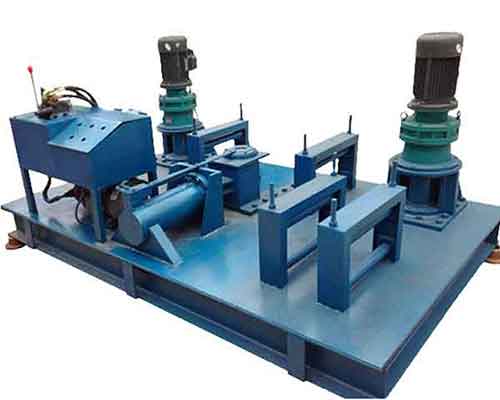

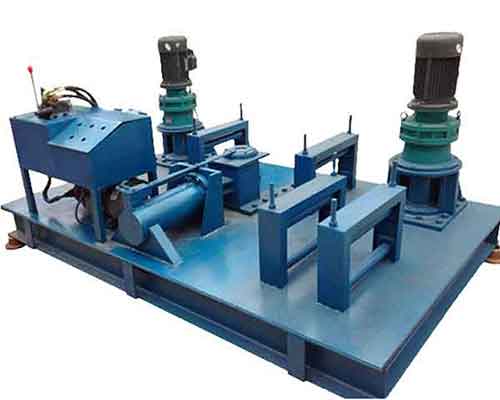

A beam bending machine, also known as the names, H-beam bending machine, I-beam bending machine, and I-beam bender is the special equipment for processing tunnel steel arch support. The processed steel arch can be widely used in the construction of railways, highways, and hydraulic tunnels, as well as bridges, and some large factory buildings. The machine is suitable for the bend of C section steel, I beam steel bar, angle steel bar, channel steel, rail, square steel, steel pipe, etc… Using the digital encoder programming to make the hydraulic control system positioning accurate, the I beam bending machine for sale in YG Machinery can make the bent steel form automatically at one time with high efficiency and convenient operation.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Technical Parameter of I Beam Bender

| Model | YGM-WGJ250 |

| Usage | 14-25 H steel beam |

| Cylinder speed | 3-3.5mm/s |

| Max Hydraulic Pressure | 25mpa |

| Hydraulic pump power | 4kw |

| Pulling Motor Power | 2.2kw x 2 |

| Minimum Bending Radius | 1.8m |

| Weight | 2200kg |

| Dimension | 2760*1640*1360mm |

The Structure of Beam Bending Machine

The I-beam bender is composed of two sets of main motor, reducer group, active roller, passive roller, oil pump motor, gear pump, overflow valve, hydraulic steering station, and working cylinder. The machine replaces the original blanking, butt joint, calibration, processing, and other complex processes, and can save oxygen, acetylene, labor, and raw materials at the same time, which is a kind of cold bending equipment with high quality and benefits.

How to Bend I Beam

First, the section steel required for cold bending should be pushed between two active rollers by a portal bracket of the auxiliary system. Then start the hydraulic system of the NC cold bending machine to make the hydraulic cylinder push the dovetail groove and cold bending roller to cold press the shaped steel. Close the hydraulic system when the required radian of the design is reached and start the mechanical transmission system to make the active roller rotate and drive the section of steel forward smoothly and slowly depending on the friction force, to realize continuous cold bending. After the cold bending operation, close the mechanical transmission system and start the hydraulic system simultaneously to retract the hydraulic cylinder. Then place the cold bending section steel on the portal bracket of the beam bending machine auxiliary system.

12 Safe Operation of I Beam Bender:

- Strictly abide by the safe operation rules of machine tools, and wear labor protection articles as required.

- Clean and wipe the upper and lower molds before starting the machine.

- Check whether there are any other things on the pallet rack, stop rack, and slide block. If there are any sundries, clean them up first.

- Select the appropriate die and the die size is generally equal to or greater than 8 times the thickness of the sheet according to the thickness of the folded sheet.

- The bending force number of the sheet metal or the calculation formula of the bending force can obtain the bending force of the workpiece. The bending force of the workpiece shall not be greater than 1000 KN.

- Please reduce the working pressure of the system appropriately to avoid damage to the mold when bending a narrow plate.

- When adjusting the stroke of the slide block, the adjustment should be less than 100 to avoid damage to the machine.

- Before bending, the clearance between the upper and lower molds should be adjusted uniformly.

- When bending I beam steel, don’t put your hand between the molds. Only one piece of material may be bent at a time. Also, check the oil level of the oil tank and start the oil pump to check whether there is any abnormality in the hydraulic pipeline and oil pump.

- The bending plate should be placed in the middle of the mold, and the machine should not be a unilateral load, so as not to affect the workpiece and machine precision. If some workpieces are required to work on one side, the load must not be more than 250KN and must be bent on both sides at the same time.

- Stop the machine immediately if there is any abnormality, check the reason, and handle the trouble in time.

- When the operation is completed, the oil pump should be closed, then exit the control system program and cut off the power.

The Outstanding Features of Beam Bending Machine in YG Machinery

- The dimensional accuracy is high, the distortion is slight, and the curvature is smooth and even.

- We can match different parts according to the different needs of users.

- High efficiency, easy transportation, and convenient operation.

- In terms of control, the procedure of the programmable Logic Controller. The fully hydraulic system automatic reader can be controlled manually or numerically.

- In the operation aspect, our machine can be unlimited feed. I beam can enter and retreat. Automatic positioning of cylinder progress dimensions without manual measurement, bending dimensions can be read automatically.

- In terms of safety, in the dual automatic shutdown system, the machine will shut down automatically when it reaches the specified size. The infrared braking system can shut down when there is no material.

Beam Bending Machine Manufacturer – YG Machinery

Henan YG Machinery Co., Ltd is a specialized manufacturer integrating R&D, manufacturing, and sales of steel processing machinery. We also have steel bar cutting machines, straightening and cutting machines, rebar threading machines, steel hoop bending machines, hydraulic punching and shearing machines, pipe shrinking machines, rebar de-rusting machines, stirrup bending machines, rebar bending machines, chain link fence machines, etc… We always adhere to the business philosophy of “quality of survival, innovation, and development”, dedicated to providing our customers with high-quality machines and satisfactory service.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

![]()