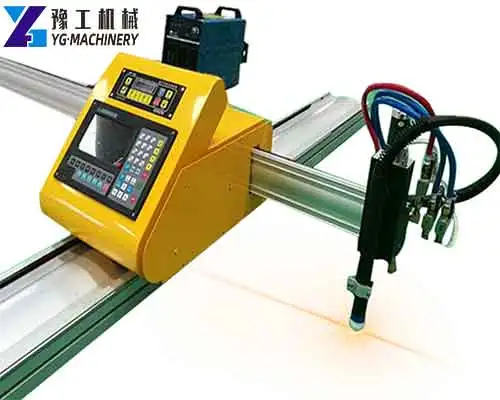

A plasma cutting machine is a machine that uses plasma cutting technology to process metal materials. Plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece and uses the momentum of the high-speed plasma to remove the molten metal to form an incision. At present, plasma cutting machines have been widely used in many fields and are very practical. And the YG plasma cutting machine price is within a reasonable range, which is accepted by the public. Want to know more details? Please contact us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Parameter of YG Plasma Cutting Machine:

| Product name | YG-1530 Fiber Laser Cutting Machine |

| Laser source | The MAX 1000W |

| CNC | Cypcut1000 |

| Machine Frame | 1500*3000mm |

| Cutting Head | The Raytools |

| Machine error accuracy | 0.02mm |

| Machine weight | 3 tons |

| Quenching process | 24 hours |

| Support max moving speed | 60m/min |

| Product name | YG-2540 gantry plasma cutting machine |

| Working area | 2500x4000mm |

| Lathe bed | Very thick steel structure |

| Machine Power | 8.5kw |

| Working voltage | 380V three-phase 60hz |

| Reposition precision | 0.02mm |

| Processing precision | 0.1mm |

| Torch Height control | China automatic ARC |

| Plasma power supply | China LGK120A |

| Control system | China SJTU-CNC |

| Motors | stepper drive motors |

| Software | ARTCAM/FASTCAM/STARCAM |

| Plasma Air Pressure | Max.0.8Mpa |

| Working Temperature | -10°C-60°C. Relative Humidity, 0-95%. |

| LCD Display Dimension | 10.0Inches |

Plasma Cutting Machine Working Principle Process:

- After the compressed air enters the cutting torch, it is distributed by the gas chamber to form plasma gas and auxiliary gas. The plasma gas arc functions to melt the metal, while the auxiliary gas cools the various parts of the torch and blows off the molten metal.

- The cutting power supply consists of two parts: the main circuit and the control circuit. The electrical principle: the main circuit includes a contactor, a three-phase power transformer with high leakage reactance, a three-phase bridge rectifier, a high-frequency arc ignition coil, and a protection element. The high leakage reactance leads to a sharp external characteristic of the power supply. The control circuit completes the entire cutting process through the button switch on the cutting torch: pre-aeration-main circuit power supply-high-frequency arc ignition-cutting process-arc recovery-stop.

- The power supply of the main circuit is controlled by the contractor; the gas flow is controlled by the solenoid valve; the control circuit controls the high-frequency oscillator to ignite the arc, and stops the high-frequency operation after the arc is established.

Scope of Application:

It can be used for the blanking of large, medium, and small plates of various metal materials such as carbon steel, manganese steel, stainless steel, and so on. A variety of cutting methods for special-shaped plates can be completed, and a plasma automatic height adjustment system is optional.

CNC Plasma Cutters Features:

- The equipment has a modular design, strong interchangeability of machine parts and components, and easier equipment function expansion. Users can configure different cutting methods according to the process requirements, such as a flame single cutting torch, flame double cutting torch, flame straight three cutting torch, flame single cutting torch + drawing machine, flame double cutting torch + drawing machine, and various specifications Plasma cutting torch and so on.

- The mechanical transmission system adopts precision rolling bearings and 7-level precision rack and pinion transmission. The gearbox adopts a precision planetary gear reducer, and the mechanical structure is equipped with an automatic backlash compensation device, so that it can achieve backlash-free transmission, ensuring the good performance and accuracy of the cutting machine.

- It can be used to blank large, medium, and small plates of various special-shaped carbon steel, manganese steel, stainless steel, and other metal materials. A variety of cutting methods for special-shaped plates can be completed, and a plasma automatic height adjustment system is optional.

- This equipment has been widely used in the shipbuilding industry, heavy machinery, chemical equipment, boiler manufacturing, rolling stock, petrochemical, and other manufacturing industries.

Advantages of Hot-sale YG CNC Plasma Cutting Machine:

- Bilateral drive.

- Smooth operation.

- High positioning accuracy.

- Strong interchangeability of parts.

- Good rigidity.

- Small inertia.

Plasma CNC Machine for Sale in YG Machinery Manufacturer:

The plasma cutting machine is a very hot-selling machine for YG Machinery this year. Many customers in Australia, the UK, South Africa, and so on are using our plasma cutting machine. Customers report that YG Machinery’s equipment is more efficient and easier to operate, and the plasma cutting machine price most cost-effective than other manufacturers’ equipment. Thank you very much for supporting our customers. In addition, we also have types of hot-selling equipment, rebar threading machines, shot blasting machines, sandblasting rooms, mortar spraying machines, fog cannon machines, hydroseeding machines, down-the-hole drilling machines, curb and gutter machines, balloon making machines, condom making machines, disposable slipper machines, wet wipe machines, disposable cup making machines, paper bag making machines, lunch box making machines, woven bag production lines, and so on. Please contact us for a free quote.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800