Excavator hydraulic rock splitter machine is also a common large-scale splitting machine. In modern life construction, construction workers can no longer use ordinary and traditional methods to operate the hard rock and boulders of the construction project. They can only split the rock through an effective and environmentally friendly physical method-splitting machine. This is the most advanced, environmentally friendly, and effective way to decompose hard rock!

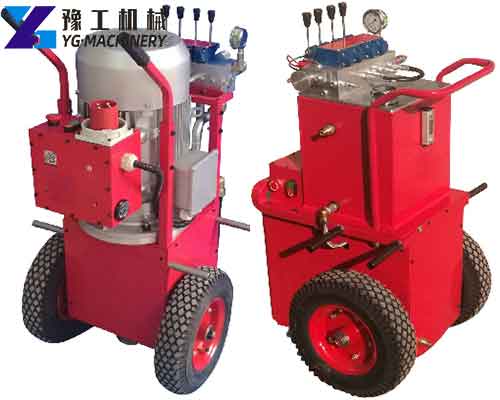

Excavator hydraulic rock splitter machine, which we usually call a large rock splitter machine, hydraulic splitting machine, etc., is a high-tech static stone crushing equipment developed and studied by YG Machinery. It uses an excavator as a platform to assist in splitting construction operations.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Excavator Hydraulic Rock Splitter Parameter:

| Model | YGM-S200 | YGM-S280 |

| Splitting Force(ton) | 3800 | 5700 |

| Piston Diameter(mm) | 200 | 250 |

| Required Drilling Diameter(mm) | 90-110 | 110-130 |

| Required Drilling Depth(mm) | 1600 | 1700 |

| Crack Width(mm) | 32 | 35 |

| Drilling Gap Distance(mm) | 1000-1500 | 2000-2500 |

| Splitting Speed(s) | 40-50 | 40-50 |

| Required Pressure(mpa.) | 60-80 | 80 |

| Splitting Gun Length(mm) | 2700 | 2800 |

| Weight(kg) | 900 | 1000 |

Working Principle of Excavator Mounted Hydraulic Rock Splitter:

The principle of the excavator hydraulic rock splitter is to increase the output pressure of the hydraulic system of the excavator through a supercharger and then drive the hydraulic cylinder of the splitter to form a driving force, which is transported to the large splitter through the hydraulic pump station of the excavator. The cylinder tube controls the push and contraction of the piston rod in the large splitting machine, and cleverly applies the principle of the wedge, which can generate a large splitting force after mechanical expansion. Although the external compressive strength of rock and concrete is very high, its internal tensile strength is relatively limited. It is precisely because of these characteristics that the splitting machine can easily split the boulder within a few seconds to split the object (such as rock, or reinforced concrete).

Construction Steps:

Select the piercing surface → drilling hole depth requirement (the depth is twice the length of the gun head, and the hole diameter is 3-5mm larger than the diameter of the gun head) → drilling position distance requirement (1-1.5 meters from the piercing surface, hole distance 1.2 —1.7m)→put the hole into the splitting machine→adjust the splitting direction→control the power station to split

Note: Every 5 to 10 holes need to be coated with high-temperature resistant grease between the split block and the wedge. This can increase the actual splitting force and also extend the life of the split block.

Hydraulic Rock Splitter Application Areas:

Mining field:

1. Mine stone mining: granite, marble, sandstone, limestone, etc.

2. Metal mine, non-metal mine, and coal mining.

3. Mining of large blocks: It can realize the rupture of a block of several thousand cubic meters.

Engineering field: municipal foundation, widely used in urban construction.

Earth and stone excavation projects: mining, stone material factories, roads and bridges, houses, foundations, and other projects.

Other areas: earthquakes, landslides, roads and railways, traffic accidents, disaster relief, etc.

The Hydraulic Splitting Machine has the Following Advantages:

- Security. The hydraulic splitting machine uses the physical characteristics of hydraulic oil incompressibility flowability, and static thrust to achieve static controllability. Therefore, there is no need to take complex safety measures, and it will not cause some hidden dangers like blasting and other impact demolition and rock drilling equipment.

- Environmental protection. Green environmental protection demolition expert—hydraulic rock splitter machine. When working, it will not produce vibration, impact, noise, dust flying debris, etc., and the surrounding environment will not be affected. Even in densely populated areas or indoors, in urban construction, and close to the equipment, you can work without interference.

- Economical. The hydraulic splitting machine has a large splitting force (the splitting force can reach 600T), so it only takes a few seconds to work at a time and can work continuously without interruption, with high efficiency; its operation and maintenance costs are very low; it does not need to be used like blasting operations isolation or other time-consuming and expensive security measures.

- Use flexibility. The user-friendly design of the hydraulic splitting machine is small in size, light in weight, and compact in structure. It ensures that its use is simple and easy to learn, requiring only one person to operate it; it can be easily dismantled and split indoors or in a narrow venue; it can also be operated underwater. Convenient maintenance and long service life.

- Accuracy. Unlike most traditional dismantling methods and equipment, the hydraulic splitting machine can accurately determine the splitting direction in advance, and can accurately dismantle and split according to the required split shape and the size of the part to be removed.

Excavator Hydraulic Rock Splitter Manufacturer – YG Machinery

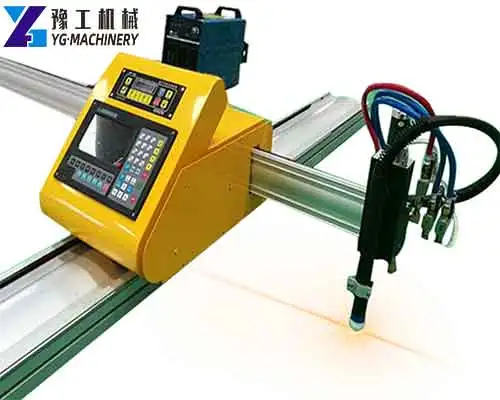

Compared with the traditional operation methods of the above-mentioned fields, the large-scale splitting machine of YG Machinery has the advantages of a huge splitting force, simple structure, convenient operation, high operation efficiency, low cost, safety, and energy-saving management. At the same time, YG Machinery also has a DTH drill machine that can be used as a complete set. There are also small hydraulic rock splitter machines suitable for small projects and supporting gasoline rock drill machines. Also, we have concrete wall saw machines, high-frequency wall saw machines, excavator hydraulic shears, pile breakers, excavator drum cutters, excavator crusher buckets, hydraulic breaker machines, firewood splitter machines, mobile crushers, etc. If you need them, please contact us immediately.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800