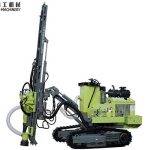

Drilling is critical in many industries such as construction, geological exploration, and mining. Truck-mounted drilling rigs combine the flexibility of trucks with the powerful drilling capabilities of drilling rigs, making them ideal for a variety of drilling operations. Whether it is water well mining, geological exploration, or engineering surveys, YG truck mounted drilling rig is perfect for your project. Contact us for more information and prices on drilling rigs.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Truck Mounted Drilling Rig Parameter:

| Model | YGC-130A | YGC-180A | YGC-200A |

| Drilling Depth | 130m | 180m | 200m |

| Opening Hole Dia. | 220mm | 180mm | 200mm |

| End Hole Dia. | 75 | 75 | 75 |

| Drill Rod Dia. | 42-60 | 42-60 | 42-60 |

| Drill Angle | 90-750 | 90-750 | 90-750 |

| Power | 13.2kw | 13.2kw | 13.2kw |

| Weight | 2750kg | 2800kg | 3000kg |

| Dimension | 4*1.7*2.3m | 4*1.7*2.3m | 4*1.7*2.3m |

| Spindle Speed | 142/285/570r/min | 130/300/480/830/1045r/min | 64/128/287/557r/min |

| Spindle Stroke | 450mm | 450mm | 450mm |

| Tractor Model | 7YP-1475DI | 7YP-1475DI | 7YP-1475DI |

| Tractor Emission Standard | GB-19756-2005(II) | GB-19756-2005(II) | GB-19756-2005(II) |

| Tractor Rated Power | 18.3kw | 18.3kw | 18.3kw |

| Tractor Rated Speed | 2200r/min | 2200r/min | 2200r/min |

| Drill Mast-Rated Load | 18T | 18T | 18T |

| Drill Mast Height | 6.5m | 6.5m | 6.5m |

| Mud Pump Displacement | 160L/min | 160L/min | 160L/min |

| Mud Pump Max. Pressure | 1.3Mpa | 1.3Mpa | 1.3Mpa |

| Mud Pump Reciprocating | 165times/min | 165times/min | 165times/min |

| Inlet Hose Dia. | 51mm | 51mm | 51mm |

| Outlet Hose Dia. | 32mm | 32mm | 32mm |

Working Principle of Truck-Mounted Drilling Rig:

The working principle of truck truck-mounted drilling rig mainly relies on its powerful power system to drive the drilling mechanism to rotate and connect the drill bit through the drill rod, using the cutting, grinding, or impact action of the drill bit to break the formation rock and soil. Different drilling methods can be selected according to different drilling needs. For example, in water well drilling, rotary drilling is usually used. Through the rotation of the drill bit and the circulation of mud, the rock cuttings are discharged out of the hole and the hole is gradually deepened. For hard rock formations, impact drilling may be used to break the rock through the impact force generated by the impactor. The entire drilling process is precisely controlled by the control system to ensure that the depth, angle, and quality of the borehole meet the requirements.

Vehicle-Mounted Drilling Rig Product Description:

YG brand truck mounted drilling rig is a highly integrated mobile drilling equipment that perfectly combines advanced drilling systems with a sturdy and durable truck chassis. The equipment usually includes the following key components:

- High-strength truck chassis: Select high-quality truck chassis to ensure the stability and driving performance of the equipment in various complex terrains.

- Sturdy drilling tower/mast: Made of high-strength steel, the structure is stable and can withstand various loads generated during drilling.

- Powerful power system: Equipped with a high-performance diesel engine and hydraulic system to provide sufficient power for drilling operations.

- Advanced drilling mechanism: According to different drilling needs, a variety of drilling methods can be configured, such as rotary drilling, impact drilling, etc.

- Reliable lifting system: Used to lift and lower drilling tools to ensure the smooth progress of drilling operations.

- Perfect control system: The operation interface is friendly and easy to use, and can achieve precise control of various functions of the drilling rig.

Functions and Technical Features of YG Brand Vehicle-Mounted Drilling Rigs:

- Excellent mobility: Based on the truck chassis, it can be quickly and conveniently transferred between different work sites, saving transportation time and costs.

- Quick deployment and withdrawal: After arriving at the work site, the equipment can quickly complete the positioning and preparation work, and can also quickly evacuate after the work is completed, improving work efficiency.

- Multiple drilling methods are available: Suitable rotary, impact, and other drilling methods can be selected according to different geological conditions and drilling needs.

- Powerful drilling capacity: It can meet the drilling needs of different depths and calibers, and can operate efficiently even in complex formations.

- High safety and reliability: Equipped with complete safety protection devices to ensure the safety of operators.

- Easy operation and maintenance: The humanized design makes the equipment easy to operate and easy to learn, and daily maintenance is relatively convenient.

Feedback from Customers Who Sold Truck-Mounted Drilling Rigs to France and Australia:

- Case 1: A large French construction company was faced with complex geology and tight construction schedules in the construction of a super-high-rise office building in the city center, and traditional drilling equipment was inefficient. After introducing the YG vehicle-mounted drill, it quickly drilled holes in hard rock formations, accurately controlled the quality of pile holes, increased construction efficiency by 3 times, and completed the project on time. The person in charge of the construction company said: “This vehicle-mounted drill is a powerful assistant for construction. Its efficient drilling performance and precise operation have enabled us to achieve good results in complex construction environments and enhance our market competitiveness.”

- Case 2: A professional geological exploration company in Australia was troubled by inconvenient transportation and complex terrain when exploring mineral resources in remote mountainous areas. After using the YG vehicle-mounted drill, it used its mobility to quickly reach the exploration site, and its powerful drilling ability to obtain high-quality core samples and discover potential gold mines. The person in charge of the geological exploration company commented: “The vehicle-mounted drill has brought revolutionary changes to exploration work, improved exploration efficiency, helped discover important mineral resources, and brought new opportunities for the company’s development.”