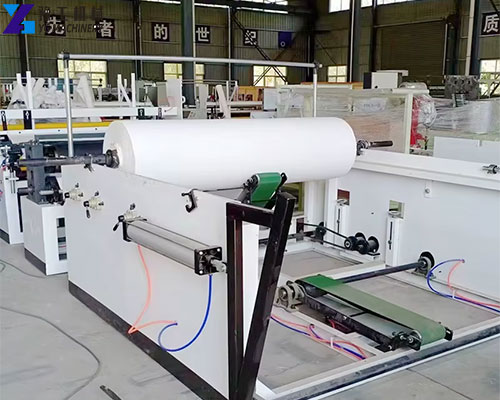

Toilet tissue paper making machine is a special equipment used to process large rolls of base paper into soft, thin rolls or pull-out toilet paper for our daily use. This type of machine usually integrates multiple functions such as base paper unwinding, embossing (to increase softness and aesthetics), perforation (to facilitate tearing), winding (rolling paper into rolls), and slitting (slitting large rolls into small rolls or cutting into pull-out tissues) to achieve automated and efficient toilet paper production. It is an indispensable piece of equipment for manufacturers of toilet paper and can produce products that meet market demand. Contact us for more product information and prices.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Toilet Tissue Paper Making Machine Parameter:

| Model | YG1575 |

| Applicable Raw Paper | 2-3 plies 14~23gsm, Wood pulp paper |

| Raw Paper Width | Max 2100mm |

| Raw Paper Dia | Max2200mm |

| Finished Size | Φ60~130 mm |

| Finished Core Dia | Φ35mm-Φ50mm |

| Raw Paper Core Dia | 3″(76.2 mm) |

| Perforation | Spiral perforating knife, Chain wheel positioning |

| Production Speed | 200 m/min |

| Parameter Design | LCD Touch Screen |

| Control | PLC |

| Paper Feeding | 3 Unwinding stands, controlled by pneumatic |

| Air Pressure | 0.5 MPs |

| Power | 380V,50hz |

| Packaging | Wooden box |

Working Principle of Toilet Roll Manufacturing Machine:

The workflow of the YG toilet paper making machine mainly includes the following steps: First, a large roll of base paper is placed on the unwinding mechanism. The base paper is smoothly conveyed to the embossing unit (if embossing is required) under the action of tension. The embossed paper enters the punching mechanism for punching to form a breakpoint that is easy to tear. Subsequently, the punched paper is wound into a roll of a preset diameter by the take-up unit. Finally, the long roll of paper is cut into finished paper rolls of the required width by the slitting unit. The entire process is precisely controlled by an advanced PLC control system to ensure the continuity of the production process and the stability of product quality.

The Toilet Tissue Paper Making Machine Has the Following Significant Functional Features:

- Highly automated: From the loading of base paper to the end product off the line, the entire production process is highly automated, greatly reducing manual intervention.

- High production efficiency: Advanced mechanical structure and control system ensure high-speed and stable operation of the equipment and increase the output per unit of time.

- Stable product quality: The precise control system ensures the consistency of parameters such as paper tension, punching spacing, and roll diameter to ensure the stability of product quality.

- Easy operation and maintenance: The humanized operation interface, simple and easy-to-understand parameter settings, and convenient and fast daily maintenance.

- Flexible production capacity: The production speed and paper roll specifications can be adjusted according to market demand to meet the customized needs of different customers.

- Energy saving and environmental protection: Optimized mechanical design and electrical control reduce energy consumption and waste in the production process.

Toilet Tissue Paper Making Machine Price – YG Machinery

In short, YG’s fully automatic and efficient toilet tissue making machine, with its excellent degree of automation, efficient production capacity, and stable product quality, has become your ideal choice to improve toilet paper production efficiency, reduce operating costs, and enhance market competitiveness. Whether you are a large paper product manufacturer or a novice seeking entrepreneurial development, our equipment can meet your needs. Contact us now to get the most competitive quotation for an exclusive toilet tissue paper-making machine.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800