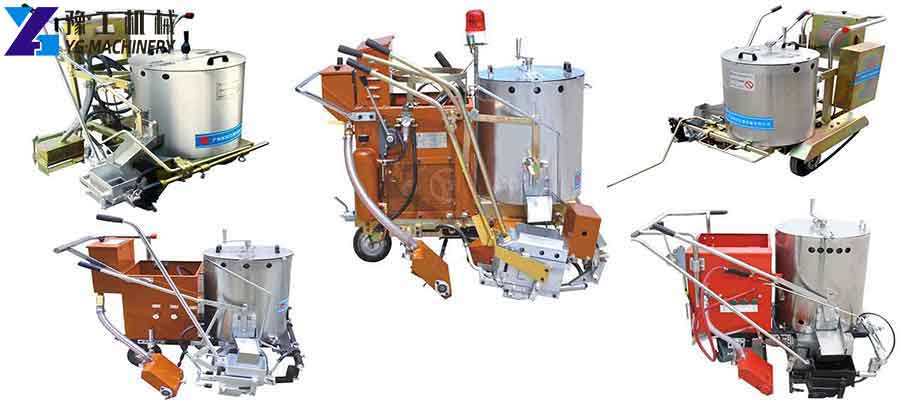

The thermoplastic road marking machine is a kind of automatic road line marking machine, which is mainly used for the painting of road traffic safety signs, such as zebra crossings, pavements, lanes, and some other road signs. It is the key equipment for the construction of hot melt road marking lines, which usually works together with the hot melt kettle to finish the marking construction. If you have requirements for different widths of the marking line, you can replace the marking hopper to complete the construction with the same hot melt road marking machine. There are various types of thermoplastic road marking machines for sale in YG Machinery, such as hand push thermoplastic road marking machines, automatic thermoplastic road marking machines, thermoplastic road marking machines for vibration lines, as well as some of its supporting equipment, such as hot melt kettle, marking hopper, waterline machine, primer machine, air sweeper machine, etc… Find the models you want and send us an email for more details now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

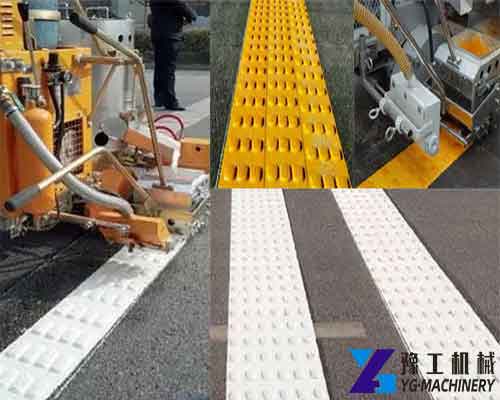

Thermoplastic Vibration Line Marking Machine

The vibration line, also known as the name of the noise marking line is a very common road marking line in daily life. It has a concavo-convex shape and the height of the base and raised part is 5-7mm. The thermoplastic vibration line marking machine is a type of road marking machinery specially designed for such lines. The thermoplastic line marking machine for the vibration line manufactured by our company uses the latest intelligent program controller and humanized control panel and realizes the method of simultaneous construction of the raised type and the baseline with one machine at the same time. The machine is equipped with a step-less variable speed walking system, which can greatly improve the construction efficiency and make the convex shape, height, and separation distance of the line precise and accurate. It can fully meet the requirements of various road conditions and meet international standards. Meanwhile, the equipment also has strong bending, wear resistance, and impact resistance.

Technical Parameters of Thermoplastic Road Line Marking Machine for Vibration Line

| Model | YG Vibration Line Thermoplastic Convex Road Marking Machine |

| Dimension | 1360*900*1100mm |

| Weight | 265kg |

| Container Capacity | 120kg (60L) |

| Glass Beads Container | 120kg (60L) |

| Engine | Honda 5.5HP/Four-stroke air-cooled gasoline engine with hand starting |

| Fuel | LPG gas |

| Driving System | HTS system with automatic brake device |

| Driving Speed | Forward 0-4km/h, backward 0-3.2km/h |

| Max. Climbing Capacity | 150 |

| Convex Height | 3-5mm (adjustable) |

| Marking Width | 150/200/250/350/400/450 mm (optional) |

Hand Push Thermoplastic Road Marking Machine

The hand-push thermoplastic road marking machine is new equipment developed by our company which can complete mark line construction independently. Engineers in our company designed the machine by learning foreign advanced technology and according to the actual road situation of our country. Through the continuous use of the engineering team of our company in the construction of road marking lines, The model with the advantages of high construction efficiency, reliable performance, simple operation, and maintenance has gradually replaced the traditional hand-push thermoplastic road marking machine. The machine is composed of a stainless steel heat insulation kettle, clutch transmission, trunk, rear-wheel positioner, glass bead box, coating bucket, heating system, and walking system.

Technical Parameter of YG-380 Thermoplastic Marking Machine

| Model | YG-380 Thermoplastic Road Marking Machine |

| Thermoplastic Paint Tank | Double stainless steel heating insulation barrels; Capacity 100kg; Plug-in manual mixer device |

| Glass Beads Container | 10kg/box |

| Adjustable Glass Beads Dispenser | Synchronized with the line; Adjustable width: 50mm-200mm |

| Marking Mold | High-precision ultra-thin material; Scraping structure; uniform and even marking line; 150mm standard equipment |

| Knife Under-frame | Carbide with adjustable eccentric sleeve |

| Scope Marking Thickness | 1-2.5mm |

| Tire | Alloy wheel with special heat-resistant rubber; Rear wheel directional steering device ensures moving in a straight line and turning freely |

| Heating Method | Liquefied petroleum gas |

| Marking Width | 50/100/150/200/250/350/400/450 mm (optional) |

| Dimension (L*W*H) | 1200mm*900mm*950mm |

| Weight | 100kg |

YG-360 Thermoplastic Paint Machine for Sale

The YG-360E Thermoplastic paint machine is more advanced than the YG-360 thermoplastic line marking machine, which has a battery device, makes it more convenient to walk, and can store electricity for up to 12 hours. Of course, the YG-360E model is a little more expensive than the YG-360 model.

Major Parameter:

| Model | YG-360 Thermoplastic Road Marking Machine |

| Thermoplastic Paint Tank | Double stainless steel heating insulation barrels; Capacity 100kg; Plug-in manual mixer device |

| Glass Beads Container | 10kg/box |

| Adjustable Glass Beads Dispenser | Synchronized with the line; Adjustable width: 50mm-200mm |

| Marking Mold | High-precision ultra-thin material; Scraping structure; uniform and even marking line; 150mm standard equipment |

| Knife Under-frame | Carbide with adjustable eccentric sleeve |

| Scope Marking Thickness | 1-2.5mm |

| Tire | Alloy wheel with special heat-resistant rubber; Rear wheel directional steering device ensures moving in a straight line and turning freely |

| Heating Method | Liquefied petroleum gas |

| Marking Width | 50/100/150/200/250/350/400/450 mm (optional) |

| Dimension (L*W*H) | 1250mm*900mm*950mm |

| Weight | 110kg |

YG-180 Thermoplastic Paint Road Marking Machine

Technical Parameter:

Dimension (L*W*H): 1400*900*1150mm

Weight: 150kg

Coating Capacity: 100kg/times

Marking width: 100/150/200/300mm

Scope Marking Thickness: 1.0-3.0mm

Speed: 1.5km/h

Heating Temperature: 180-230℃

Heating Mode: Petroleum liquefied gas

Get a Free Quote

Hot Melt Kettle

A hot melt kettle is one of the main pieces of equipment for the construction of a thermoplastic road marking line. The equipment is very simple to operate. First, pour some of the coatings into the machine for heating and melting. When the coating temperature reaches 180 to 200 degrees, start the blender to stir and keep adding new paint. When the temperature of the coating inside the kettle reaches 190 to 210 degrees and all paints are in a flow state, put into the liquid coating into the marking machine through the discharge port for construction. We usually divide the machine into mechanical hot melt kettle and hydraulic hot melt kettle according to the power and it also includes two types, single-cylinder, and double-cylinder. The main difference between the single cylinder and double cylinder is the difference in capacity. The mechanical hot melt kettle is mainly unidirectional stirring, while the hydraulic model is bidirectional stirring. Purchase the model you need now.

Mechanical Hot Melt Kettle with Single And Double Cylinder

The Advantages of Thermoplastic Road Marking Machine for Sale in YG Machinery

- Don’t need to be equipped with a hot melt kettle and the appearance is beautiful, the body is light and compact.

- Lift type of handlebar design that operators can make adjustments according to their needs.

- Glass microbead automatic spreader.

- The detachable design of the heat insulation drum and the reasonable design of the stirring shaft solve the problem of material stored in a mixing tank.

- An adjustable pointer can improve work efficiency.

- The coating bucket made of a high-precision steel plate has the characteristics of high-temperature resistance, corrosion resistance, deformation resistance, and rapid heating.

- The wheels made of cast iron and imported rubber are very light, strong, and durable.

Automatic Thermoplastic Road Marking Machine for Sale

Thermoplastic road marking machines for sale in YG have high automation. With the advantages of convenience to use, long service life and low maintenance cost, high working efficiency, the machine is very popular with customers. So no matter which country or region you come from in the world, if you would like to buy a road marking machine, please feel free to tell us more about your requirements, our sales manager will send you a quotation as soon as they can.

Thermoplastic Road Marking Machine Manufacturer – YG Machinery

In addition to the thermoplastic road marking machine, we can also manufacture cold paint road marking machines, as well as some other kinds of road construction machinery, such as floor shot blasters, floor scarifier machines, mini road roller machines, trowel machines, concrete curb machines, electric road sweepers, asphalt crack filler machines, concrete scabblers, floor grinder machines, etc… All the machines have been exported to many countries all over the world and received high praise from customers for quality and price. Want to buy machinery from YG Machinery, don’t hesitate to contact us for more details now.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800