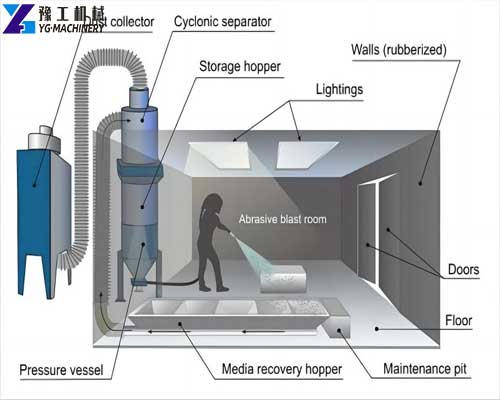

The sandblasting booth is a closed working environment used for sandblasting the surface of workpieces. By spraying abrasives at high speed, the oxide layer, rust, oil stains, etc. on the surface of the workpiece are removed to achieve the purpose of cleaning, roughening, and forming. It is widely used in the surface treatment of metals, glass, plastics, and other materials. Now more and more customers choose sandblasting rooms for their projects to improve efficiency. If you are also interested, please feel free to contact us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Sandblasting Room for Sale in YG Machinery Parameter:

| Size of Blasting Room | Size of workpieces | Blasting Gun Qty |

| 6000×6000×5000mm | 3000×3000×2500mm | 2 |

| 6000×6000×6000mm | 3000×3000×3500mm | 2 |

| 8000×6000×5000mm | 5000×3000×2500mm | 2 |

| 8000×6000×6000mm | 5000×3000×3500mm | 2 |

| 10000×6000×6000mm | 7000×3000×3500mm | 2 |

| 15000×6000×6000mm | 12000×3000×3500mm | 2 |

| 15000×8000×6000mm | 12000×5000×3500mm | 2 |

| 18000×8000×6000mm | 15000×5000×3500mm | 4 |

| 18000×10000×8000mm | 15000×7000×5500mm | 4 |

Dust Collector for Sandblasting Room:

The dust collector is one of the most important parts of the sandblasting room. YG Machinery’s cartridge dust collectors are designed to fit each room, depending on the size of the room, the sandblasting parts, the amount of dust generated by the sandblasting media, and the size of the airflow.

Advantages:

1. Quick, easy, and safe replacement of filter cartridges

Replacing the filter cartridges is done outside the dust collector without any tools. This eliminates the need to work in a confined space and workers can access the filter cartridges without dirtying them.

2. Continuous operation

The cartridge dust collector removes and cleans dust particles from the filter without stopping operation.

3. Economical

The cartridge dust collector is an economical choice because it requires little maintenance: only the filter cartridges need to be replaced regularly.

Sandblasting Booth Advantages:

- All our products are designed in 3D, which is more accurate, more intuitive, and more convenient for project demonstration and drawing review.

- A new scraper conveying system is used to collect abrasives. A cylinder drives each scraper, and the foundation depth is only 350mm, which can reduce the foundation cost by 70~80%.

- Our company has a sandblasting pot production workshop. Our company produces all dry sandblasting pots and dust-free wet sandblasting pots to ensure the quality of each component and are not purchased from outside. The product manufacturing technology is very mature and the sandblasting operation is very stable.

- The electronic control system is essential. Our company produces the entire electronic control system to ensure quality. (Programming, assembly).

Why More and More Customers Choose YG Sandblasting Room?

Sandblasting room is a kind of rust removal equipment, that can replace traditional slab rust-re-moved technique. While changing the surface roughness, it can also remove welding slag, burrs, and flash. High efficiency, low cost, and good quality, unmatched by traditional chemical and other rust removal equipment. Which is primarily for cleaning big steel structural parts, vessels, and truck chassis to remove the rusty spots, rusty layer, and scale cinder on steel to obtain a uniform, smooth,h and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. The main feature of the sandblasting room is that the operator works in the sandblasting chamber, and manually controls the blasting gun to finish the blasting work, which can ensure 100% rust removal. Protective clothing and helmet protect the operator from abrasive shock and ventilation provides fresh air through the helmet. Sand blasting room has many advantages. Firstly, it can complete the treatment of a large number of parts in a relatively short period. Secondly, the manual blasting room can handle objects of different shapes and sizes and is suitable for a wide range of materials and surface treatment requirements. In addition, manual sandblasting rooms can use many different types of grit, such as glass beads, aluminum oxide, steel balls, etc., to achieve different surface effects. Of course, we also have portable sandblasting machines, automatic sandblasting machines, dry ice blasting machines, etc. Contact us for more details!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800