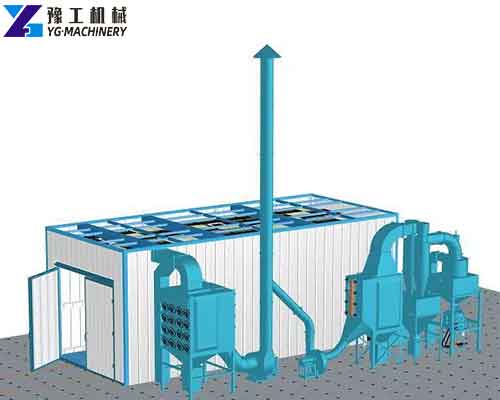

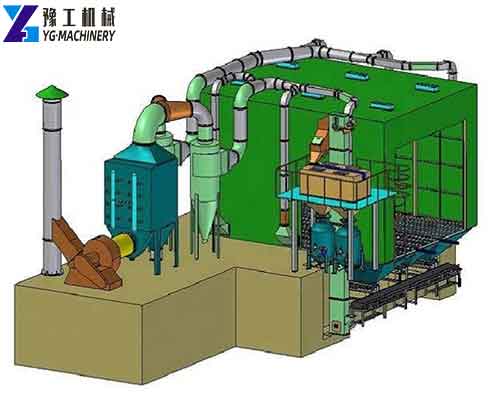

The sandblasting chamber is also called the shot blasting machine and the sandblasting room. It is suitable for surface cleaning and rust removal of some large workpieces and increases the adhesion between the workpiece and the coating. The sandblasting room is designed according to the production process and the characteristics of the product itself. Suitable for surface de-rusting and rust removal of large castings, welded steel structures, engineering machinery, industrial boilers, chemical machinery, shipbuilding, etc. Strengthen, improve the adhesion of paint, and so on. In addition, we also have pass-through shot blasting machines, hanger-type shot blasting machines, floor shot blasters, portable sandblasting machines, and dry ice blasting machines for all customers. If you are interested in our machines, please feel free to contact us. 【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Sand Blasting Room Parameters:

| Size of Blasting Room | Size of workpieces | Blasting Gun Qty |

| 6000×6000×5000mm | 3000×3000×2500mm | 2 |

| 6000×6000×6000mm | 3000×3000×3500mm | 2 |

| 8000×6000×5000mm | 5000×3000×2500mm | 2 |

| 8000×6000×6000mm | 5000×3000×3500mm | 2 |

| 10000×6000×6000mm | 7000×3000×3500mm | 2 |

| 15000×6000×6000mm | 12000×3000×3500mm | 2 |

| 15000×8000×6000mm | 12000×5000×3500mm | 2 |

| 18000×8000×6000mm | 15000×5000×3500mm | 4 |

| 18000×10000×8000mm | 15000×7000×5500mm | 4 |

Best YG Sandblasting Cabinet Features:

- Economic, efficient, and pollution-free.

- Complex workpieces of all sizes are well-machined.

- Reduce working noise and extend service life.

- Provide dust-free protective accessories to ensure operator health.

- Equipped with advanced PLC systems and high-quality components.

- The size of the blasting room can be custom-designed.

The Design of the Blasting Booth Must Meet the Following Requirements:

- Painting works normally in all weather.

- The process equipment can operate at full load for a long time without trouble, and the whole of the sandblasting and painting booth adopts a” no-fault” design; a Grid board.

- The central centralized control system should meet the requirements of simple operation and a high degree of automation of the process equipment system.

- The processing system should be advanced, practical, and safe.

- Improve the overall cost performance of the system by optimizing the design.

- Economical, reasonable, and comfortable ventilation, dust removal, and paint mist treatment.

- The production capacity of sandblasting and painting is basically up to the design requirements.

- System equipment must be advanced and complete, and reduce the dependence on auxiliary services.

Check the Difference Between a Sand Blasting Machine and a Sand Blasting Chamber:

In terms of external dimensions, sandblasting machines are generally small equipment, and sandblasting rooms are built in a house for sandblasting. The sandblasting machine is generally simpler than the sandblasting room. Sandblasting chambers’ structure and supporting equipment are mainly composed of six parts: shot blasting room, shot blasting system, abrasive circulation system, ventilation, and dust removal system, lighting, and electrical control system.

The automatic sandblasting room is a kind of sandblasting machine, which uses compressed air as the power and metal abrasive as the medium. The automatic sandblasting room automatically refers to automatic blasting, the automatic workpiece in and out, automatic oscillating of the spray gun, automatic sorting of abrasives, automatic dust removal, and so on. Anyway, except for the top and bottom of the workpiece, all of them do not require manual operation. Suitable for flat plates, discs, squares, etc.

Large Sandblasting Cabinet Use Scale:

- Pre-disposal: Electroplating, painting, spraying, etc. All are covered by sandblasting before processing, the appearance is hygienic, and the adhesion and corrosion resistance of the cover layer are greatly improved.

- Finishing: Metal parts such as castings, stampings, welded parts, heat treatment parts, descaling, residue, and dust; Non-metallic products, surface finishing, ceramic blanks, black spots, and lacquer drawings.

- The old parts innovation: Innovative cleaning of all moving parts such as automobiles, motorcycles, sandblasting room mechanical, and electrical equipment. Together to eliminate fatigue and stress and extend the service life.

- The light decoration: All metal products and non-metal products ( plastic, crystal, glass, etc.) surface traces are eliminated, and argon light fog surface treatment, is so that the appearance of the product is promoted to the level.

- The touch tool disposal: The argon surface treatment of the mold surface, the graphic production, and the mold finishing do not hurt the appearance of the mold, and guarantee the precision of the mold.

- Burr disposal: Fine burrs of machined parts are removed, and the overflow of the injection parts is eliminated.

- Rework of defective products: Removal of poor masking of the product, the poor coloring of the appearance, and the removal of printing.

- Strengthening: Adding the hardness of the metal parts to eliminate stress, such as aircraft blades, springs, machining tools, and weapons.

- Etching anti-skid processing: Metal products, non-metal products, exterior etching pictures, text, and anti-slip treatment, such as marble, handle slip, seal, and stone lettering.

- Denim disposal: Denim wears matte, whitish, and hairy effects.

![]()