The concrete road paver machine is used to spread the mixed cement concrete along the roadbed according to the given thickness, width, and road type requirements, and then through the operation procedures of tapping, leveling, and troweling, to complete the construction of the paved concrete pavement mechanical. We also sell road marking machines, floor shot blasters, road rollers, asphalt crack filler machines, floor grinder machines, concrete curb machines, etc. for sale in YG Machinery with high quality and the best price. If you are interested in our machine, please contact us now to know more details.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Concrete Road Paver Parameter:

| Model | YG-168 Double roller | YG-219 Three rollers |

| Paving width | 3000-6000mm | |

| Vibration frequency | 32HZ | |

| Roller diameter | 168mm | 219mm |

| Impact force | 5.5kN | |

| Move speed | 8-10m/min | |

| Voltage | 380v | 380v |

| Weight | 1000kg | 1500kg |

| Power | 4kw +4kw | 4+5.5kw |

| Paving thickness | 300mm | |

Concrete Road Paver Use and Classification:

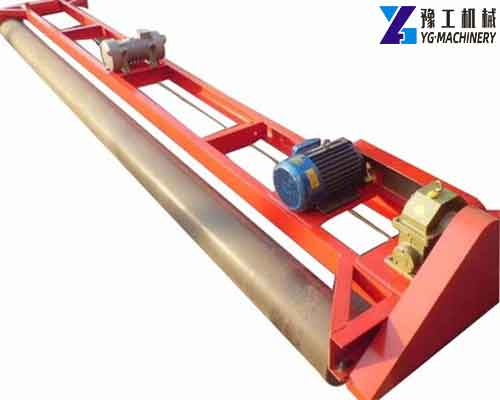

According to the roller, it is mainly divided into two types of rollers (168 types) and three rolls (type 219). One axis is responsible for walking, one axis is responsible for leveling, and the other is responsible for pulping. It can also be equipped with a screw shaft ( skein shaft) called a four-roller. This shaft mainly plays the role of scraping the material and reducing the burden on several shafts, making the paving effect more obvious.

It is mainly used for paving and leveling the concrete surface of high-speed railways, bridges, municipal roads, country roads, airport runways, water slopes, and other projects.

Road Paver Machine Main Functions:

They were paving various materials such as road base and surface layers, leveling, tapping, slurrying, and leveling, solving road surface flatness, improving mechanized paving ability, and speeding up construction progress.

The shaft of the roller paver is made of a 6mm seamless steel pipe, the diameter of the shaft is 219, and the motor has two, the traveling motor and the vibration motor. The voltage is 380V and the leveling depth can reach 30cm. This machine is fully automatic, with brake effect, paving, compaction, pulping, and equalization functions, and the leveling effect is particularly good. Widely used in various roads, squares, airport runways, and other concrete roads. Machines of different lengths can be customized according to your requirements, up to 12 meters.

Pavers Start-up Notes:

- The road paver machine should be fully preheated before paving so that the temperature of the screed reaches about 100 degrees. Only when sufficient heating is performed, the occurrence of the pulling phenomenon of the pavement at the initial stage of paving can be avoided.

- When the paver is in place, the screed of the paver should be parallel with the seam of the road as much as possible, and the front end of the screen should be as close as possible to the seam. It is easy to cause unevenness in the road when it is advanced.

- Before the paver starts, the paver hammer should be able to rotate freely. Generally, the hammer is manually pulled, and then the paver hammer is idling for a few minutes, knowing that the hammer can rotate at a normal speed. Otherwise, due to the large resistance, the hammer belt slips easily during the starting process, and the hammer speed is unstable, resulting in a large change in compactness and uneven thickness of the paving, which affects the flatness of the joint.

- When the paver starts, it should be placed on the screen under the appropriate thickness of the wooden board. The thickness of the board is determined according to the thickness of the paving compaction, combined with the mechanical condition and experience. Pay attention to the board’s position, which should be evenly arranged at the back end of the screen.

- When the paver starts, the elevation angle of the screed should be adjusted. According to the work experience, the working elevation angle of the screen is generally adjusted to the position of the elevation angle of the paver at the end of the previous day’s construction. For new paving, the paver’s elevation scale is generally adjusted to the paver’s paving thickness plus the value of 3-5. Experience is important to consider the screed’s elevation position, paving material, paving thickness, temperature changes, equipment status, and more.

- The paver should be squared and slow at the start. After the indicators are qualified, adjust to the normal paving speed.

Concrete Road Paver Machine Price – YG Machinery Manufacturer

In recent years, there have been more and more types of paving equipment, concrete laser leveler machines, road pavers, trowel machines, road rollers, and so on. But this small concrete road paver is relatively economical, low in price, simple to operate, and is the first choice of many customers. In addition, we have other road construction equipment, road marking machines, floor shot blasters, crack filler machines, concrete curb machines, electric road sweepers, etc. Contact us to know more!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()