Paper egg trays, renowned for their eco-friendliness and durability, have gained widespread acceptance as an alternative to plastic egg cartons. In the ever-evolving world of food packaging, the automated paper egg tray making machine has revolutionized the egg packaging industry. These machines, powered by cutting-edge technology, streamline the production of paper egg trays, enhancing the final product’s quality, minimizing environmental impact, and boosting overall productivity. Click here to know the paper egg tray making machine price!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Paper Egg Tray Making Machine Parameter:

| Model | YG-1*3 | YG-1*4 | YG-3*4 | YG-4*4 | YG-4*8 | YG-5*8 | YG-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kW) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

Benefits of Paper Egg Tray-Making Machines:

- Environmental Sustainability: These machines significantly reduce waste and promote circular economy principles by utilizing recycled paper. The end products are fully biodegradable, minimizing landfill burden and mitigating the use of non-renewable resources.

- Cost-Effectiveness: Automation streamlines production, reducing labor costs and enhancing production speeds. In the long run, this translates into cost savings for manufacturers and consumers alike.

- Product Quality & Safety: Paper egg trays offer excellent protection to eggs, minimizing breakage during transport and storage. They are also free from harmful chemicals commonly found in plastic alternatives, ensuring food safety.

- Versatility: These machines can be customized to produce trays of varying sizes and configurations, catering to the industry’s diverse needs.

- Brand Enhancement: For businesses, adopting eco-friendly packaging solutions can bolster their corporate image and appeal to an increasingly environmentally conscious consumer base.

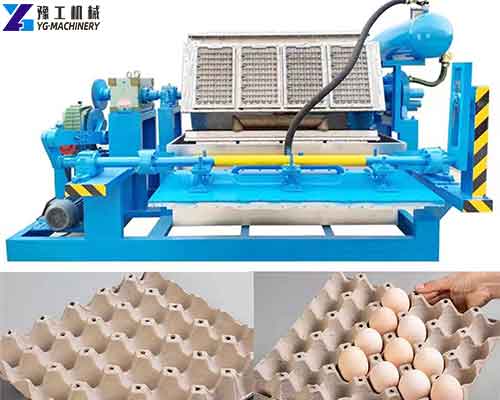

How Paper Egg Tray Making Machines Work:

At the heart of these machines lies a sophisticated process that transforms recycled paper pulp into sturdy yet lightweight egg trays. The process begins with the preparation of paper pulp, typically made from waste paper collected from various sources. This pulp is then fed into the machine, where it undergoes a series of precise operations:

- Pulp Formation: The paper pulp is mixed with water to form a homogeneous mixture, ready for molding.

- Molding: The pulp mixture is poured into custom-designed molds, each designed to create the characteristic egg-shaped compartments that securely cradle the eggs.

- Draining & Drying: Excess water is drained off, and the trays are conveyed through a drying system that utilizes heat or air circulation to remove moisture, solidifying the structure.

- Demolding & Trimming: Once dried, the trays are automatically ejected from the molds and trimmed to ensure uniform dimensions.

- Packaging & Dispatch: Finally, the trays are stacked, packaged, and dispatched for use in egg farms, supermarkets, and food processing facilities.

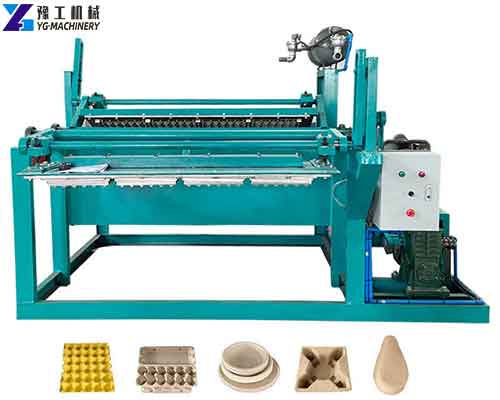

Paper Egg Tray Making Machine for Sale in YG Machinery

By combining efficiency, sustainability, and cost-effectiveness, these machines are transforming the way eggs are packaged and transported. As more and more countries adopt stringent regulations on single-use plastics, the popularity of paper egg trays is expected to soar. The role of automated paper egg tray making machines in shaping the future of egg packaging becomes increasingly vital. Yugong Machinery has also been deeply involved in the paper products industry for many years. We also have paper cup making machines, paper bowl making machines, paper straw making machines, paper dish making machines, paper carton making machines, paper cup printing machines, roll die cutting machines, egg tray production lines, etc. Contact us for more machine details!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()