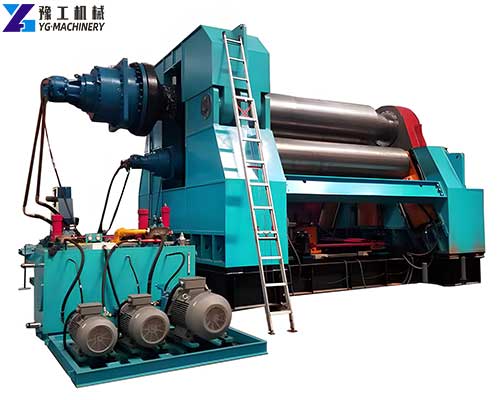

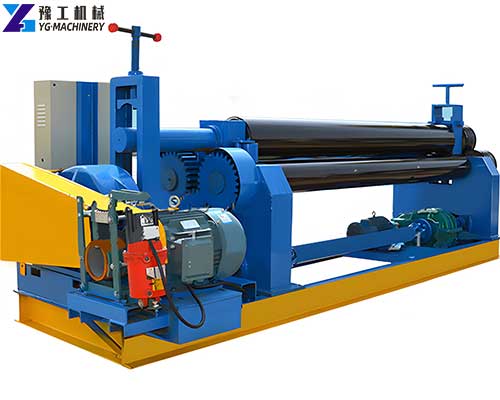

As an important sheet metal processing equipment, the metal plate rolling machine plays an indispensable role in Russian industrial production. As a traditional industrial power, Russia has a strong manufacturing base and a large demand for metal plate rolling machines. Our customer had a clear demand for the machine and the finished product, so our communication was simple and efficient. We quickly determined the machine model, and the subsequent communication and payment were very smooth. If you also need a steel plate rolling machine, please contact us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Metal Plate Rolling Machine Parameter:

| Model | Max Pre-bending

Thickness (mm) |

Max

Rolling Thickness (mm) |

Max

Rolling Width (mm) |

Plate Yield

Limit (MPA) |

Rolling

Speed (m/min) |

Upper

Roller Dia (mm) |

Lower

Roller Dia (mm) |

Side

Roller Dia (mm) |

Motor

Power (KW) |

| 6×2000 | 6 | 6 | 2000 | 265 | 5.5 | 180 | 180 | 145 | 5.5 |

| 6×2500 | 6 | 6 | 2500 | 265 | 5 | 210 | 210 | 165 | 7.5 |

| 8×2000 | 6 | 8 | 2000 | 265 | 5 | 215 | 215 | 165 | 11 |

| 8×2500 | 6 | 8 | 2500 | 265 | 5 | 230 | 230 | 180 | 11 |

| 12×2000 | 10 | 12 | 2000 | 265 | 5 | 260 | 260 | 200 | 18.5 |

| 12×2500 | 10 | 12 | 2500 | 265 | 5 | 280 | 280 | 220 | 18.5 |

| 16×2000 | 12 | 16 | 2000 | 265 | 5 | 280 | 280 | 220 | 18.5 |

| 16×2500 | 12 | 16 | 2500 | 265 | 5 | 330 | 330 | 260 | 22 |

| 16×3200 | 12 | 16 | 3200 | 265 | 5 | 360 | 360 | 280 | 30 |

| 20×2000 | 16 | 20 | 2000 | 265 | 5 | 330 | 330 | 260 | 22 |

| 20×2500 | 16 | 20 | 2500 | 265 | 5 | 360 | 360 | 280 | 30 |

| 25×2000 | 20 | 25 | 2000 | 265 | 5 | 360 | 360 | 280 | 30 |

| 25×2500 | 20 | 25 | 2500 | 265 | 4.5 | 410 | 400 | 320 | 37 |

| 30×2000 | 25 | 30 | 2000 | 265 | 4.5 | 410 | 400 | 320 | 37 |

| 30×2500 | 25 | 30 | 2500 | 265 | 4.5 | 470 | 470 | 390 | 37 |

| 30×3000 | 25 | 30 | 3000 | 265 | 4.5 | 560 | 520 | 420 | 45 |

| 40×2500 | 35 | 40 | 2500 | 265 | 4.5 | 560 | 520 | 420 | 45 |

| 40×3000 | 35 | 40 | 3000 | 265 | 4.5 | 650 | 580 | 480 | 55 |

| 50×2500 | 40 | 50 | 2500 | 265 | 4 | 650 | 620 | 500 | 55 |

| 50×3000 | 40 | 50 | 3000 | 265 | 3.5 | 720 | 650 | 520 | 55 |

| 60×3000 | 50 | 60 | 3000 | 265 | 3.5 | 750 | 710 | 560 | 75 |

| 70×3000 | 60 | 70 | 3000 | 265 | 3 | 750 | 720 | 600 | 75 |

| 80×3000 | 70 | 80 | 3000 | 265 | 3 | 800 | 780 | 620 | 75 |

| 90×3000 | 80 | 90 | 3000 | 265 | 3 | 840 | 820 | 660 | 90 |

| The above data is only for reference, to prevail in kind. More specifications are available. | |||||||||

Advantages of Metal Plate Rolling Machine:

- High efficiency: High degree of automation, production efficiency is much higher than traditional manual processing.

- Flexibility: Processing parameters can be quickly adjusted according to different workpieces and processing requirements.

- Safety: Equipped with a variety of safety protection devices to ensure the safety of operators.

- Strong adaptability: Can process metal plates of various materials and thicknesses.

Characteristics of Russian Customers’ Requirements for Metal Plate Rolling Machines:

- Cold resistance: Russia has a cold climate, and the equipment needs to have good cold resistance to adapt to harsh working conditions.

- Reliability: Russian customers have high requirements for the reliability of equipment, hoping that the equipment can run stably for a long time and reduce downtime.

- Easy to operate: Russian workers have high requirements for the operation of equipment, and the operation interface of the equipment should be simple intuitive, and easy to learn.

- Cost-effectiveness: When choosing equipment, Russian customers will comprehensively consider factors such as equipment performance, price, and after-sales service, and pursue cost-effectiveness.

Typical Application Cases:

- Petrochemical industry: Russian petrochemical enterprises use metal plate rolling machines to manufacture various storage tanks, reactors, and other equipment. These equipment need to withstand high pressure and temperature, so the material and welding quality of the equipment are required to be high.

- Shipbuilding industry: Russian shipbuilding enterprises use metal plate rolling machines to process large curved structures such as hulls and bulkheads. These parts have extremely high requirements for dimensional accuracy and shape accuracy, and the high-precision processing capabilities of metal plate rolling machines meet this demand.

- Pressure vessel manufacturing: Russian pressure vessel manufacturing companies use metal plate rolling machines to manufacture various pressure vessels, such as boilers, heat exchangers, etc. These equipment have extremely high requirements for welding quality and sealing performance.

- Construction engineering industry: Russian construction engineering companies use metal plate rolling machines to process various metal plates for roofs, walls, and other parts of buildings. The flexible production capacity of metal plate rolling machines enables them to adapt to the characteristics of multi-variety and small-batch production in construction projects.

Case Analysis:

Case 1: A large petrochemical enterprise in Russia

- Requirement: Manufacturing storage tanks with large diameter and thick wall thickness requires equipment with high load-bearing capacity and forming accuracy.

- Solution: Provided a four-roller heavy-duty metal plate rolling machine, which has a strong rolling capacity and precise size control function to meet customer needs.

Case 2: A shipyard in Russia

- Requirement: Processing large-area curved plates of hulls requires equipment with high efficiency and good dimensional stability.

- Solution: Provide a CNC metal plate rolling machine, that uses an advanced CNC system to achieve automated production, improving production efficiency and product quality.