The concrete laser leveling machine, also named the concrete laser screed machine, is mainly used for paving concrete for engineering buildings. It mainly uses the laser transmitter and the leveling machine to complete the leveling, vibrating, and finishing work of the whole concrete. The machine uses a squeegee to take the raised shovel and initially level it to meet the design requirements. The hydraulically driven vibration motor generates vibration at a frequency of 4000 times per minute, which drives the entire vibrating plate to vibrate together. The concrete laser leveling machine has a construction width of 2.5-3 meters. If you are interested in our machine, please contact us now.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Concrete Laser Leveling Machine Product Parameters:

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, stepless speed | Handle control, stepless speed | Handle control, stepless speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

Working Principle of Concrete Laser Leveling Machine:

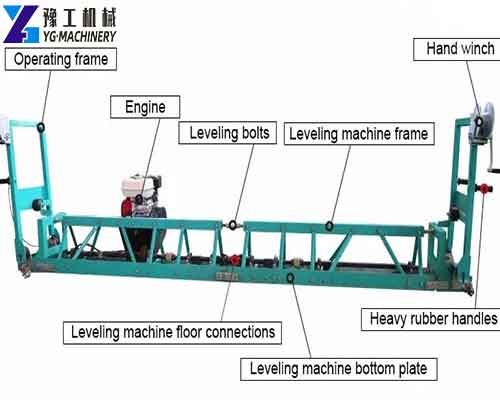

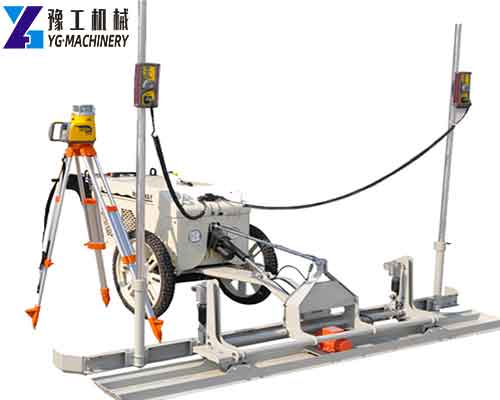

The machine is divided into a hand-held type and a seat type. The principle of the laser leveling machine is to rely on the gasoline generator to generate electricity. The electric drive laser measurement and control system, the computer control system, and the servo drive system use the leveling head to complete the leveling work. The whole machine is composed of the fuselage and the leveling head. The flat is mainly completed by the flattening head part, which includes: a scraper, a vibrating unit, a vibrating plate, a laser receiver, and the like. The instruments used with the machine are laser emitters, hand-held laser receivers, etc.

Features of the Laser Concrete Leveling Machine:

- Use high-accuracy laser devices, closed-loop control technology, precision integrated hydraulic systems, and microcomputer automatic control.

- Screed assembly is hydraulically controlled. Integrated with a laser and computer control system, the machine will self-level and finish the screeding work with high efficiency.

- The Laser transmitter, which measures the elevation, is independent and located, so there is no worry about cumulative error. Compared with the traditional way, the construction joints will be greatly reduced, so the maintenance cost and slab use will greatly decrease.

- The flat and dual slope can be fully automatically controlled by the transmitter. For the complex floor that has high requirements for drainage, the 3D floor processing system can be used.

- The forward-seated operation can widen operator vision, reduce labor intensity, and improve working efficiency

- The steering, forward, and reverse of the machine are all controlled by integrated handles. The operation buttons and controllers, located on one side of the seat, are user-friendly.

- The machine with a solid puncture-proof tire can do the screeding on the mat reinforcement.

- The high-pressure cleaning system can easily remove the concrete from the machine to ensure normal use and prolong the service life.

YG Laser Receiver for Sale:

The laser receiver is rechargeable and can be used for 20 hours on a single charge ( 6-8 hours full), covering a radius of 100 meters.

Working Principle:

The laser transmitter generates a rotating laser. The laser receiver on the leveling machine receives the signal and is analyzed by the laser measurement and control system. The deviation is fed back to the sensitive computer control system on the leveling machine. The left and right electric pushrods will adjust the scraper. Height, ensuring leveling accuracy.

Definition:

Definition of laser leveling machine: A machine that is guided by a laser and used to level and level concrete.

Definition of laser leveling: When constructing a large-area concrete floor, a laser leveling machine is used to vibrate, level, and control the concrete construction method of the newly poured concrete.

The laser leveling technology mainly uses the laser transmitter and the leveling machine to complete the leveling, vibrating, and leveling work of the whole concrete. Firstly, a fixed laser emitter is set, and the laser beam emitted by the transmitter is rotated to form a laser control plane. The floor elevation is guided to the leveling head of the floor concrete laser leveler by using a hand-held receiving rod, and the automatic control on the leveling machine is started. The system will adjust the laser signal ( at a frequency of 10 times/second) automatically according to the laser signal sensed by the laser receiver on the leveling head. Because the laser transmitter is fixed after being set up, it can ensure the construction of a large area of ground. Accumulated errors are generated, and the error can be reduced to within 3mm.

Concrete Laser Leveling Machine Price – YG Machinery Manufacturer

Now, more and more customers use laser levelers to replace ordinary levelers/pavers. It is not only efficient but also labor-saving. Our machines are advanced and intelligent, and can set up multi-language screens. In YG Machinery, we have many other types of road construction machinery, such as road-making machines, road roller machines, floor shot blasters, asphalt crack filler machines, floor grinder machines, floor scarifiers, curb and gutter machines, electric road sweepers, mini excavators, and so on. Contact us to get a free quote!【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

![]()