In modern industrial production, surface treatment is crucial. Traditional cleaning methods often have problems such as low efficiency and environmental pollution. As an emerging green cleaning technology, laser cleaning technology is increasingly favored by various industries for its advantages such as high efficiency, environmental protection, and non-destructiveness. As our recent sales champion, this machine has solved a big problem for many customers and their projects have been completed. If your project also requires a laser cleaning machine, please contact us now to get a free latest quote.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

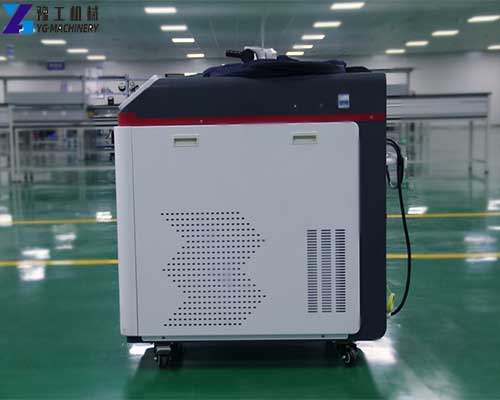

Hot-sale Portable Laser Cleaning Machine Parameter:

| Machine Model | YG-1000W | YG-1500W | YG-2000W |

| Laser Power | 1000W | 1500W | 2000W |

| Laser Wavelength | 1064-1080nm | 1064-1080nm | 1064-1080nm |

| Welding Depth | 2mm | 4mm | 7mm |

| Modulation Frequency | 20-20kHz | 20-20kHz | 20-20kHz |

| Energy Stability | <3% | <3% | <3% |

| Blowing Protection | Argon/Nitrogen | Argon/Nitrogen | Argon/Nitrogen |

| Electricity Demand | AC 220V/50Hz | AC 220V/380V/50Hz | AC 220V/380V/50Hz |

| Machine Power | 5.6KW | 7.1KW | 9.1KW |

| Cooling System | Water | Water | Water |

| Dimension | 1130x590x1200mm | 1130x590x1200mm | 1130x590x1200mm |

| Weight | 230kg | 230kg | 230kg |

Advantages of Laser Cleaning Technology

Laser cleaning uses a high-energy laser beam to irradiate the surface of the workpiece, instantly vaporizing or peeling off the dirt, rust, coating, etc. on the surface, thereby achieving the purpose of cleaning. Compared with traditional cleaning methods, laser cleaning has the following significant advantages:

- Efficient and fast: Laser cleaning is fast and efficient, which can significantly shorten the production cycle.

- Environmentally friendly and pollution-free: No need to use chemical agents, no wastewater, waste gas, or other pollutants will be generated, and it is environmentally friendly.

- Non-destructive cleaning: Laser cleaning is a non-contact cleaning method and will not cause mechanical damage to the workpiece surface.

- Precise and controllable: The parameters of the laser can be precisely controlled to achieve precise cleaning of specific areas.

- Wide range of applications: Can be used to clean various materials, such as metal, plastic, glass, ceramics, etc.

- High degree of automation: This can be integrated with automated equipment to achieve automated production.

Application Fields of Laser Cleaning Machine

Laser cleaning technology is widely used in the following fields:

- Metal surface treatment: rust removal, oxide scale removal, oil removal, welding slag removal, etc.

- Mold cleaning: cleaning injection molds, tire molds, rubber molds, etc.

- Aerospace: cleaning aircraft parts, engine blades, etc.

- Automobile manufacturing: cleaning auto parts, welding parts, etc.

- Electronic industry: cleaning PCB boards, electronic components, etc.

- Cultural relics restoration: cleaning dirt, oxides, etc. on the surface of cultural relics.

- Petrochemical industry: cleaning pipes, containers, etc.

Successful Case: Portable Laser Cleaning Machine Application by Polish Customers

We have successfully provided an automated laser cleaning system to a Polish automotive parts manufacturer. The company mainly produces automobile chassis parts. The traditional pickling and rust removal method has problems such as low efficiency and serious pollution. After using our laser cleaning system, they successfully solved these problems:

- Significantly improved production efficiency: Laser cleaning is fast, greatly shortening the production cycle.

- Reduced environmental pollution: No need to use pickling fluid, avoiding the generation of pollutants such as wastewater and waste gas.

- Improved product quality: The laser cleaning effect is uniform and consistent, which improves the surface quality of the product.

- Reduced production costs: Reduced labor costs and environmental protection processing costs.

Why Choose YG Laser Cleaning Machine?

- Technology leadership: We have advanced laser cleaning technology and rich industry experience.

- Product quality reliability: Our products are strictly quality-controlled and tested.

- Customized solutions: We can provide customized solutions according to customer needs.

- Perfect after-sales service: We provide timely technical support and after-sales service.

Laser Cleaning Machine for Sale in YG Machinery – Factory Price

We offer various types of laser cleaning machines for sale, aiming to provide efficient and environmentally friendly surface treatment solutions for various industries. Our product line includes handheld, portable, desktop, and automated laser cleaning systems, covering pulsed and continuous laser technology, which can effectively remove metal rust, oil stains, coatings, welding slag, etc., and are widely used in automotive manufacturing, aerospace, mold cleaning, cultural relics restoration and other fields. Whether you need fine cleaning of a small area or efficient rust removal of a large area, we can provide suitable equipment and customized solutions. We are committed to providing high-quality products, competitive prices, and professional after-sales service. Contact us now to learn more about laser cleaning machines and get a free quote.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800