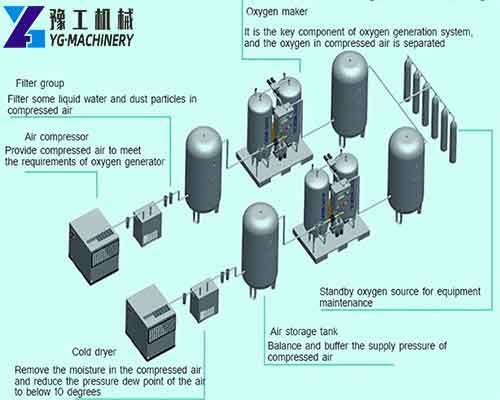

Industrial oxygen generator production equipment, as the name suggests, is the equipment used for the production of oxygen in industrial production. The oxygen production equipment in my country is generally composed of air compressors, pre-cooling devices, purification devices, and air separation towers. YG Machinery also has portable nitrogen generators. If you are interested, please contact us for more information. 【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Medical Oxygen Generator Parameter:

| Model No. | Flow Rate | Purity |

| YGFO-5 | 5 | 93±2% |

| YGFO-10 | 10 | 93±2% |

| YGFO-20 | 20 | 93±2% |

| YGFO-30 | 30 | 93±2% |

| YGFO-40 | 40 | 93±2% |

| YGFO-50 | 50 | 93±2% |

| YGFO-60 | 60 | 93±2% |

| YGFO-70 | 70 | 93±2% |

| YGFO-80 | 80 | 93±2% |

| YGFO-100 | 100 | 93±2% |

| YGFO-120 | 120 | 93±2% |

| YGFO-150 | 150 | 93±2% |

| YGFO-180 | 180 | 93±2% |

| YGFO-200 | 200 | 93±2% |

The Working Principle of Oxygen Generator:

According to the principle of pressure swing adsorption, zeolite molecular sieves are used as adsorbents. Due to the selective adsorption characteristics of zeolite molecular sieves, nitrogen is largely adsorbed by zeolite molecular sieves, oxygen is enriched in the gas phase, and nitrogen and oxygen separation is achieved under the action of pressure swing adsorption. Two adsorption tower processes are adopted, one is for adsorption and oxygen production, and the other is for desorption and regeneration. The opening and closing of the pneumatic angle seat valve are controlled by a PLC intelligent program so that the two towers are cycled alternately and continuously produce high-quality oxygen.

Main Application Areas:

Medical treatment, petrochemical industry, plateau airport, locomotive, post, metallurgy, papermaking, biotechnology, etc.

Features of Oxygen Generator:

- Low investment cost.

- Low use cost and low daily maintenance costs.

- The stability of the equipment system is guaranteed to a certain extent.

- Advanced manufacturing technology.

- Integration of production, sales, repair, and maintenance.

The Workflow of Industrial Oxygen Generator:

After the air is compressed by the air compressor, the cubic oxygen generator enters the air storage tank after dust removal, oil removal, and drying, and enters the left adsorption tower through the air intake valve and the left intake valve. The pressure of the cubic oxygen generator increases. The nitrogen molecules in the compressed air of the cubic oxygen generator are adsorbed by the zeolite molecular sieve, and the unadsorbed oxygen passes through the adsorption bed and enters the oxygen storage tank through the left gas production valve and oxygen gas production valve. This process is called left suction and the duration is Dozens of seconds.

After the left suction process is over, the left adsorption tower and the right adsorption tower are connected through a pressure-equalizing valve to balance the pressure of the two towers. This process is called pressure equalization, and the duration is 3 to 5 seconds. After the pressure equalization is over, the compressed air enters the right adsorption tower through the air intake valve and the right intake valve. The nitrogen molecules in the compressed air of the cubic oxygen generator are adsorbed by the zeolite molecular sieve, and the enriched oxygen passes through the right gas production valve and oxygen gas production. The valve enters the oxygen storage tank. This process is called the right suction and lasts for tens of seconds.

At the same time, the oxygen adsorbed by the zeolite molecular sieve in the left adsorption tower is released back into the atmosphere through the left exhaust valve. This process is called desorption. On the contrary, when the left tower is adsorbing, the right tower is also desorbing at the same time. To completely discharge the nitrogen released by the depressurization of the molecular sieve into the atmosphere, the oxygen gas passes through a normally open back-purge valve to purge the desorption adsorption tower, and the oxygen in the tower is blown out of the adsorption tower. This process is called backflushing, and it is carried out simultaneously with desorption.

After the right suction is over, it enters the equalizing process, then switches to the left suction process, and the cycle continues.

Advantages of Oxygen Generator Products:

- Excellent energy-saving technology, reducing gas costs.

- Use a high-quality molecular sieve for oxygen generation (UOP imported from the United States) to ensure maximum energy saving of the device.

- Using advanced process configuration, the equipment is safe, stable, and reliable.

- On-line monitoring of oxygen purity and flow rate, and automatic system start/stop function.

- Select the special valve imported from Germany that is frequently switched over 3 million times without barriers to ensure the stable operation of the system.

- The selection of international brand components is an effective guarantee of equipment quality.

- The special alumina ceramic ball diffusion technology makes the airflow evenly distributed and improves the adsorption efficiency of the adsorbent.

- Using SIEMENS or OMRON product PLC programmable controller, high control precision, stable operation, and fully automated operation.

- The exquisite and beautiful man-machine interface can display various parameters of the system, and can also adjust related parameters according to user needs.

- The maintenance rate is low. The equipment is maintained once a year, and only a small amount of work such as replacing the activated carbon and the filter element can ensure the operation of the equipment throughout the year.

- The equipment operation and maintenance training system is comprehensive, the after-sales service responds promptly, and the equipment return visits are carried out regularly to truly make users feel at ease.

- Environmental protection and pollution-free: no three wastes discharged, no environmental pollution.

- According to the parameters provided by the customer, tailor-made.

![]()