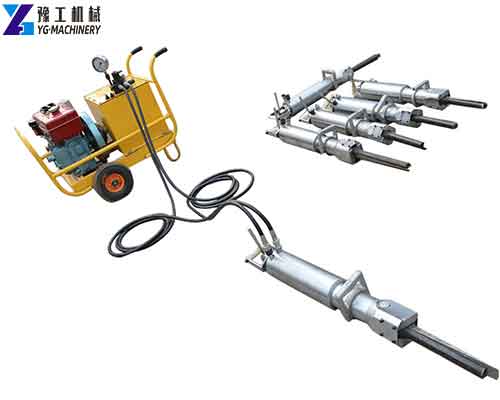

The hydraulic stone splitter is also known as a rock splitter, stone splitter, mountain breaker, etc. At present, the most popular ones are electric and diesel splitters. This product is mainly used for the mining of building stones; secondary disintegration of large ores (metallic ores, non-metallic ores); partial and complete demolition of concrete components (cement pavement, machine tool foundation, bridge, and house components); natural stone mining, splitting and crushing. Compared with the traditional operation methods in the above fields, it has the advantages of simple structure, convenient operation, high efficiency, low cost, safety, energy saving, etc. This product is particularly suitable for the secondary splitting of large rocks and can be used with a gasoline rock drill. It is an ideal equipment that can replace blasting and manual disintegration.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

The Parameters of Hydraulic Rock Splitter:

| Model | YG-250 | YG-350 | YG-450 |

| Wedge Length(mm) | 250mm | 350mm | 450mm |

| Piston Stroke(mm) | 90/220mm | 90/220mm | 90/220mm |

| Drilling Depth(mm) | >500mm | >700mm | >900mm |

| Punching Diameter(mm) | 42mm | 46mm | 46mm |

| Crack Width(mm) | 10-20mm | 10-20mm | 10-20mm |

| Cleavage Time(s) | 10-15/s | 10-15/s | 10-15/s |

| Splitting Force(T) | 500t | 800t | 800t |

| Weight(kg) | 240kg | 250kg | 260kg |

Why Choose YG Hydraulic Rock Splitter?

- The rock splitter can be controlled to operate in a static hydraulic environment, and there will be no dangers like blasting machines and other impact removal and rock drilling equipment, and there is no need to take complicated safety measures.

- During operation, there will be no vibration, impact, noise, dust, flying debris, etc. The surrounding environment will not be affected, and it can operate without interference even in densely populated areas or indoors, as well as next to precision equipment.

- The rock splitter can complete the splitting process in a few seconds and can operate continuously without interruption, with high efficiency, low operating and maintenance costs, and no need to take isolation or other time-consuming and expensive safety measures like blasting operations.

- Unlike most traditional removal methods and equipment, the rock splitter can accurately determine the splitting direction, splitting shape, and required part size in advance, with high splitting accuracy.

Different Applications Area of Rock Splitter Machine:

1. Quarrying and Mining Industry

- Mining of large blocks; mining of blocks of thousands of cubic meters can be achieved.

- Splitting of large blocks; making blocks of less than 1 cubic meter can be achieved.

- Removal of large waste rocks and leveling of sites.

2. Construction Projects

- Tunnel excavation.

- Extension of underground mine tunnels.

- Highway culverts and tunnel excavation.

- Subway tunnel excavation.

- Undersea tunnel excavation.

- Underground artificial river excavation.

- Pipeline tunnel excavation.

- Excavation of artificial rivers and rock ditches.

- Foundation excavation.

3. Demolition Projects

- Demolition of concrete and reinforced concrete.

- Demolition of old houses.

- Demolition of old buildings.

- Demolition of old bridge piers.

- Removal of old ground.

- Removal of chimneys.

- Underwater removal. ①Cleaning of river channels. ②Demolition of underwater buildings. ③Removal of underwater buildings in ports.

IV. Chemical, smelting production, and overhaul projects.

- Overhaul of smelting furnaces.

- Overhaul of electrolytic aluminum electrolytic cells.

- Removal and construction of various furnace refractory bricks.

- Crushing of carbon blocks in carbon plants.

V. Various emergency rescue and disaster relief.

- Removal of mine disasters, fires, landslides, flood relief, and other removal work.

- Emergency rescue of large-scale traffic accidents on railways and highways.

Hydraulic Stone Splitter for Sale in YG Machinery Manufacturer

Through the above explanation, we clearly understand that static blasting rock splitter, as an advanced, efficient, safe, and multi-purpose engineering equipment, has become an indispensable magic weapon in the field of modern engineering construction. It has made significant contributions to key factors such as improving construction speed, ensuring construction safety, and controlling construction costs. It is believed that rock splitting machines will be more widely used and promoted in future engineering practices. In addition, we also have excavator rock splitters, excavator drill and splitting machines, excavator pile breakers, excavator rock saws, excavator hydraulic shears, excavator crusher buckets, excavator drum cutters, mobile crushers, firewood splitters, etc. Contact us to know more machine details!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800