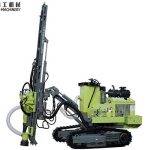

Concrete hydraulic rotary drilling rig is a kind of engineering machinery that uses hydraulic power and rotary drilling to carry out pile foundation construction. It integrates multiple functions such as drilling, hole forming, wall protection, and slag cleaning. It is mainly used to drill pile holes in the ground to lay a solid foundation for the foundations of buildings, bridges, tunnels, and other structures. Especially in projects that require deep pile foundations such as high-rise buildings and large bridges, it is an indispensable core equipment. Do you also want to buy a rotary drilling rig? Contact us now.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Hydraulic Rotary Drilling Rig Parameter:

| Dimensions (mm) | 7900*2260*3100 |

| Vehicle mass (kg) | 8000 |

| Wheelbase (mm) | 3150 |

| Wheelbase (mm) | Front 1400 After 1060 |

| Drilling depth (m) | 13 |

| Drilling diameter (mm) | 600-1600 |

| Rotation angle | 180 degree |

| Walking speed (km/h) | 50 |

| Gear pump model | CBJT2080 |

| Hydraulic system working pressure (Mpa) | 20-25 |

| Hydraulic system displacement (ml/r) | 80 |

| engine model | 4108 |

| Engine power (kW) | 88 |

Hydraulic Rotary Drilling Rig Working Principle:

The hydraulic rotary drilling rig is mainly composed of key parts such as a power system, hydraulic system, drill rod drive device, drill frame, and control system. The power system usually uses a high-power diesel engine or electric motor to provide a stable and strong power source for the equipment. The hydraulic system is the “power transmission hub” of the entire drilling rig. It converts mechanical energy into hydraulic energy through an oil pump, under the guidance of precise pipelines and control valves, high-pressure oil drives each actuator to work.

The drill rod drive device can achieve high-speed rotation of the drill rod under the action of the hydraulic system. During the drilling process, the drill rod drives the drill bit to rotate, and the drill bit rubs against media such as rock or soil, thereby breaking the rock and soil body and realizing the drilling operation. At the same time, the hydraulic system can also accurately control the feed speed and lifting speed of the drill rod, and flexibly adjust the drilling parameters according to different geological conditions and drilling requirements. The drill frame provides a stable support structure for the drill rod and drill bit to ensure the stability and accuracy of the drilling process. The control system integrates advanced sensors and operating interfaces, through which operators can monitor various parameters during the drilling process in real-time, such as drilling depth, drilling pressure, rotation speed, etc., and make precise adjustments based on actual conditions.

How to Choose a Suitable Hydraulic Rotary Drilling Rig?

- Clarify the project requirements: clarify your project type (construction, bridge, municipal, etc.), pile diameter, pile depth, geological conditions (soil layer, rock layer, pebble layer, etc.), construction period requirements, construction site conditions (narrow, flat, mountainous, etc.).

- Determine the tonnage of the drilling rig: According to the pile diameter, pile depth, and geological conditions, choose the appropriate tonnage of the drilling rig. The larger the pile diameter, the deeper the pile depth, and the harder the geology, the larger the tonnage, and the more powerful the rotary drilling rig needs to be.

- Choose the appropriate drill rod type: According to the drilling depth and geological conditions, choose a telescopic drill rod or a friction drill rod. The number of sections, single section length, and material of the telescopic drill rod also need to be selected according to the specific working conditions.

- Choose the appropriate drill bit type: According to the geological conditions, choose the proper drill bit type. Choose a spiral drill bit or a barrel drill bit for the soil layer; choose a rock drill bit for the rock layer; choose a hole expansion drill bit for hole expansion.

- Consider chassis type: Choose a crawler, walking, or wheeled chassis according to construction site conditions. The width, length and ground pressure of the chassis also need to be evaluated according to site conditions.

- Evaluate brand and quality: Rotary drilling rigs are large equipment, and quality and reliability are directly related to construction efficiency, safety, and maintenance costs. It is also important to examine the manufacturer’s production scale, technical strength, and after-sales service.

- Pay attention to the intelligent configuration: The intelligent configuration of modern rotary drilling rigs is becoming more and more important, such as automatic vertical adjustment, automatic pressurization, intelligent monitoring, remote diagnosis, etc.

- Compare price and cost performance: Comprehensively consider factors such as equipment performance, quality, brand, after-sales service, and operating costs, and choose the most cost-effective solution to maximize investment returns.