The hydraulic combined punching and shearing machine is a sheet metal and profile processing equipment that integrates multiple functions. Hydraulic combined punching and shearing machine is widely used in the production of steel structures, storage shelves, high-voltage wire towers, telecommunications towers, street lamps, advertising signs, elevators, ventilation pipes, and other civilian facilities.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

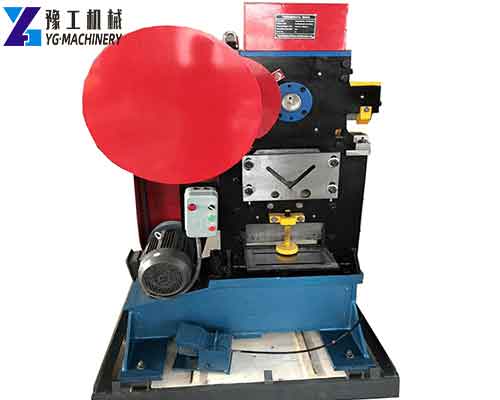

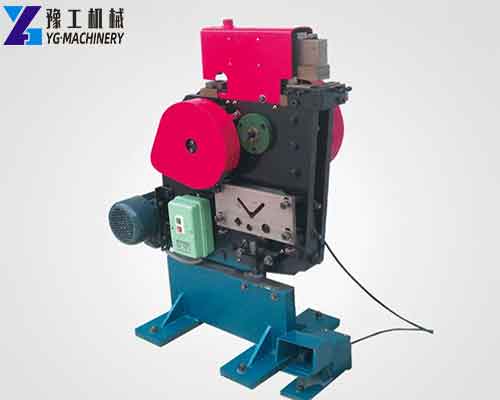

QA32-8B Hydraulic Combined Punching and Shearing Machine:

QA32-8B hydraulic combined punching and shearing machine is a newly designed product of our company. It is a series of products in the machinery industry. It has a novel design, compact structure, beautiful appearance, reliable performance, small size, lightweight, many functions, quick operation, and use. Convenient, widely used for cutting metal sheets, shaped metal and punched shaped metal, holes, and die shearing, is the real equipment for cutting and stamping shaped metal. Serving customers in the machine-building industry.

Main Feature:

- Excludes the hydraulic combined punching and shearing machine, hydraulic components and electrical parts are prone to failure and oil leakage.

- Easy to operate, high cutting precision can be programmed to set the width and number of cut sheets.

- The power required for shear, low power consumption, energy-saving, low noise, and no pollution.

- Advanced manufacturing structure and fewer wearing parts.

|

Technical Parameter |

||

| Type | QA32-8B | QA32-12B |

| Max. punching force | 360KN | 900KN |

| Length of cutter for plate cutting | 200mm | 300mm |

| Cutter travel distance | 27mm | 36mm |

| Number of strokes | 30/min | 30/min |

| Power of electric motor | 2.2kw | 4KW |

| The voltage of the electric motor | 380V(220V/240V) | 380V(220V/240V) |

| Size | 900*500*1100mm | 1100*600*1450mm |

| Weight | 500kg | 1100kg |

Q35Y-25 Hydraulic Combined Punching and Shearing Machine:

Main Feature:

- Cut and pinch all kinds of materials such as plates, square bars, angles, round bars, channels, etc.

- Bend the plate below 500mm.

- All the components are of the highest quality in their safety, function, capability, and maintenance.

|

SPECIFICATIONS FOR HYDRAULIC IRONWORKER |

|||||

| Specification | Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 |

| Process Capacity | 60T | 90T | 110T | 140T | |

| Punching | Dia.(punch)*Thickness(mm) | 25*16 | 30*20 | 35*25 | 38*26 |

| Ram Stroke(mm) | 80 | 80 | 80 | 80 | |

| No. of stroke(times/min) | 8 | 8 | 6 | 6 | |

| Cutting | Max. the thickness of the plate (mm) | 16*250 | 20*330 | 25*330 | 30*355 |

| Max. width of plate (mm) | 8*400 | 10*480 | 16*600 | 20*600 | |

| Angle Shearing | 90°shearing (mm) | 125*12 | 140*12 | 160*14 | 180*16 |

| 45° shearing (mm) | 50*5 | 50*5 | 60*6 | 60*6 | |

| Notching

|

Thickness (mm) | 16 | 20 | 25 | 26 |

| Width (mm) | 25 | 30 | 35 | 38 | |

| Depth (mm) | 300 | 350 | 400 | 600 | |

Prepare Before Starting Up:

- The lubrication of each transmission part should be sufficient, and each lubrication point should be refueled 2-3 times per shift to ensure sufficient oil quantity at each lubrication point.

- Check that the cutting tool and the punching tool should be intact without cracking and fastening.

- Observe that the gap between the punch and the lower die wall should be uniform, in line with the punching and shearing requirements, the minimum configuration of the punch should slightly exceed the plane of the lower die hole.

- The electric insulation and grounding of the equipment must be guaranteed.

Operation Steps and Specifications:

The Operation Steps:

- Check the power supply condition, the voltage is stable, there is no phase loss, and the leakage protector and the air switch are intact.

- Wiring, open the joint punching machine wiring cabinet, connect the line, and close the door.

- Press the footswitch after power-on, the machine does not move, the power cord is interchanged, and the emergency stop switch is checked.

- At work, be careful to turn off the power every time you change the mold during work.

- Turn off the switch after the work is finished, turn off the main power switch, unplug the power cord, and clean the debris.

Safety Practices:

- Ordinary and E-type punching and type cutting can not work at the same time, L-type machines ( double-linking punching and shearing machines) can work synchronously.

- It is strictly forbidden to cut hardened steel and exceed the equipment capacity for processing.

- The cutting props and cutting edges should be sharp, the cutting edge becomes dull or cracked and should be replaced in time.

- When cutting steel plate, round steel, square steel, and section steel, it must be compacted. There should be no weld bead, gas-cutting tumor, and protruding burr on the surface of the sheared sheet.

- When cutting or punching, it is strictly forbidden to touch the surface of the processed workpiece by hand. It is strictly forbidden to measure the workpiece, and the scarp should not be cleaned directly by hand.

- The operator must stop when leaving the machine. When driving, check the original position of the handles of each part.

- It is not allowed to cut the laminated sheets, and it is not allowed to cut the narrow sheets and short materials that are not tight.

- When two or more people work together, one person must command and act in unison.

- When feeding, the finger must be away from the knife edge by 200mm, and special tools should be used for small parts.

- During use, pay more attention to observing whether the side rotation screw of the punching cylinder is loose and the clearance is too large. Pay attention to timely inspection and adjustment.

- In use, check whether the friction block bolts and the caps on both sides of the fuselage are loose, and make timely tightening work to prevent tool damage.

- Use the mid-check check switch and the stopper to prevent the travel switch positioning baffle from loosening or cutting off the stroke control range to generate the parallel cylinder and the backup pressure, which causes the machine to be punched and sheared, the noise is large and the oil pump, the oil pipe, and the oil cylinder are damaged.

The Handling of Abnormal and Emergency Situations:

It is strictly forbidden for non-designated personnel to operate the equipment. The user must be familiar with the instruction manual of the punching machine and have certain operating techniques. Usually, people must be disconnected from the machine.

Shutdown Follow-up Work:

- Turn off the power and clean the work site.

- Check the equipment to ensure that the equipment is in good condition and carry out routine maintenance as required.

Ironworker Machine Maintenance and Maintenance Rules:

- Operate in strict accordance with the operating procedures.

- Before each start-up, according to the instructions, the lubrication diagram requires timing, fixed point, and quantitative lubrication. The oil should be clean and free of sediment.

- The tabletop must be kept clean and the unpainted parts must be coated with anti-rust grease.

- Always check whether the electrical part is working properly and safely.

- Regularly check the repair switch, insurance, and handle to ensure reliable operation.

- 10 minutes before work every day, lubricate the machine and lubricate the machine.

Hydraulic Combined Punching and Shearing Machine Manufacturer – YG Machinery

As a professional manufacturer of various types of small machinery, the production of road machines is our main business, including floor shot blasters, road marking machines, mini road rollers, floor scarifiers, trowel machines, asphalt crack filler machines, floor grinders, concrete curb machines, etc… We also sell rebar straightening and cutting machines, rebar threading machines, beam bending machines, auto pipe bending machines, steel hoop bending machines, stirrup bending machines, rebar bending machines, steel bar cutting machines, reinforced cage winding machines, chain link fence machines, pipe shrinking machines, etc. If you would like to purchase a hydraulic combined punching and shearing machine, you can send us an email from this page for a quotation now. And if you are interested in other kinds of machinery in our company, you can visit the appropriate page to check more or contact us directly. We will reply to you in 24 hours.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800