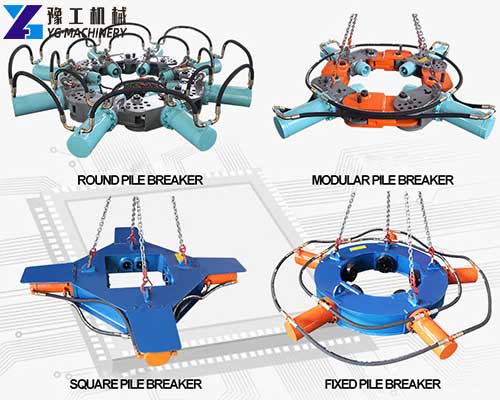

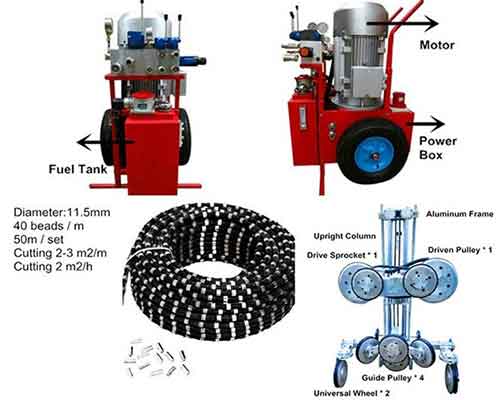

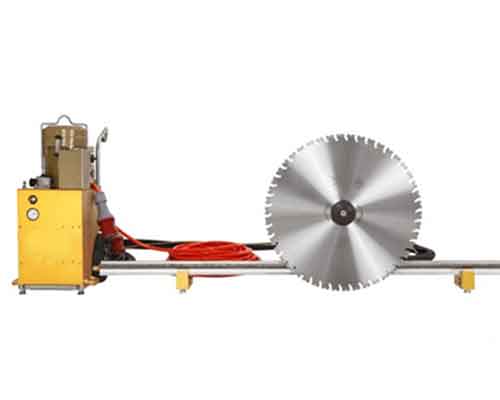

In the past few years, hydraulic rock splitter has been relatively rapid development as well as wide application. Along with the continuous deep development of the global economy, the construction of resource and energy development and infrastructure shows huge market potential, the global market demand for splitting machine equipment is expanding, and the demand for equipment performance is becoming higher and higher. It has become more and more difficult to manually lift mountains or break rocks, and for environmental protection requirements, explosives cannot be used. As a result, cutting and demolition machinery has become increasingly popular. Now we also have hydraulic rock splitters, large splitting machines(excavator hydraulic rock splitter), and pile breaker machines that can be used in engineering projects.

Hydraulic rock splitting machine, also called a hydraulic splitting machine, concrete splitting machine, and rock splitting machine, are all other names for the hydraulic rock splitting machine. The hydraulic splitting machine is hydraulic equipment that uses an ultra-high pressure power station to carry out hydraulic oil-driven hydraulic splitting to carry out rock splitting. It uses a hydraulic splitting machine to carry out mining, and its efficiency is more than 3 times higher than that of breakers. Hydraulic splitting machine Open-pit mining, cave mining, and secondary rock decomposition can be carried out.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Working Principle of Hydraulic Rock Splitter:

- Start the electric or diesel-powered hydraulic pump station and activate the pump station reversing valve to make the pressure enter the oil pipe.

- Turn on the reversing valve handle on the gun body to the position of the white hydraulic pipe joint. At this time, the powerhead of the splitting gun extends outwards, the oil pressure reaches 60Mpa, and the splitting machine starts to split stones.

- After splitting the stone, the reversing valve on the gun body is turned to the black joint position, and the powerhead moves upward and returns to the position.

- When the powerhead is recovered and the oil pressure rises, move the handle to the middle position (neutral position) to unload the oil, and pull out the gun body from the rock for the next operation.

- After the rock-splitting operation is completed, the oil pressure should be relieved, and the pump station motor or diesel engine should be turned off to avoid excessive oil temperature.

Application of Cutting Machinery:

Mining field:

- Mining of mine stone: granite, marble, limestone, etc.

- Mining of metal mines, non-metal mines, and coal mines.

- Mining of large blocks: It can realize the second splitting and breaking machine for a block of several thousand cubic meters.

- Segmentation of large blocks: The splitting of blocks below 1 cubic meter can be realized.

- Remove large pieces of waste rocks, dead ends, obstacles, leveling the ground, etc.

Engineering field: municipal foundation, widely used in urban construction.

- Earth and rock excavation work roads and bridges, houses, foundations, reinforced concrete demolition, and other works.

- Tunnel excavation projects: subways, culverts, mines, underground pipelines, river treatment, and other projects.

- Smelting and dismantling projects: crushing and dismantling of various smelting furnaces, kilns, refractory bricks, and carbon blocks.

Other areas:

Earthquakes, landslides, road and railway traffic accidents, disaster relief, etc.

The above description shows that the splitter is suitable for working places such as narrow sites and blind demolition where large equipment is not easy to enter. The splitting machine is a kind of mechanical equipment that can replace the secondary blasting and dismantle it by hand.

![]()