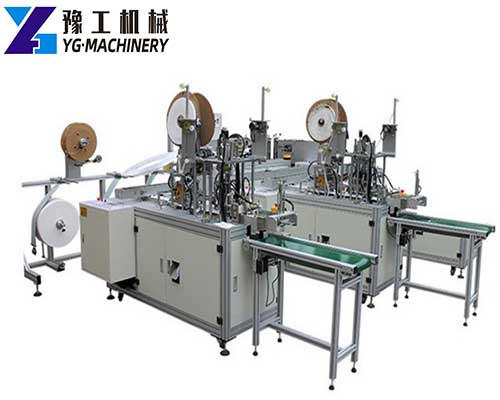

The disposable glove making machine has stable performance and the production line of PVC liquid latex nitrile semi-dip machine. Applicable materials include PVC liquid/Latex/Nitrile. Of course, at YG Machinery we also sell face mask making machines, meltblown production lines, balloon making machines, condom making machines, wet tissue machines, tissue making machines, diaper manufacturing machines, and other protective equipment. Escort your health. Please contact us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Glove Making Machine Parameter:

| Model | Machine size (m) | Speed (m/min) | Output(pcs/hr) | Heat consumption(cal/hr) | Power(kW/hr) | Mould(pcs) | Chain(m) |

| YG-SBA50*6 | 50*1.8*6.5*6layers | 8.3 | 5000 | 450000 | 32 | 3000 | 300 |

| YG-SBA60*6 | 60*1.8*6.5*6layers | 10 | 6000 | 550000 | 34 | 3600 | 360 |

| YG-SBA80*6 | 80*1.8*6.5*6layers | 13.3 | 8000 | 750000 | 45 | 4800 | 480 |

| YG-SBA100*6 | 100*1.8*6.5*6layers | 20 | 12000 | 1100000 | 70 | 6000 | 600 |

| YG-SBA110*6 | 110*1.8*6.5*6layers | 21.6 | 13000 | 1200000 | 75 | 6600 | 660 |

| YG-SBB80*6 | 80*1.8*9*6layers*2 | 13.3 | 16000 | 1400000 | 90 | 9600 | 480 |

| YG-SBB100*6 | 100*1.8*9*6layers*2 | 18 | 21600 | 2100000 | 100 | 12000 | 600 |

| YG-SBB110*6 | 110*1.8*9*6layers*2 | 20 | 24000 | 2200000 | 110 | 13200 | 660 |

| YG-SBA60*8 | 60*1.8*13*8layers | 10 | 7200 | 730000 | 45 | 1800 | 480 |

| YG-SBA80*8 | 80*1.8*13*8layers | 16.7 | 10000 | 1100000 | 65 | 6400 | 640 |

| YG-SBA100*8 | 100*1.8*13*8layers | 22 | 13200 | 1470000 | 70 | 8000 | 800 |

| YG-SBA110*8 | 110*1.8*13*8layers | 24 | 14400 | 1600000 | 80 | 8800 | 880 |

| YG-SBB80*8 | 80*1.8*13*8layers*2 | 16.6 | 20000 | 1900000 | 120 | 12800 | 640 |

| YG-SBB100*8 | 100*1.8*13*8layers*2 | 20 | 24000 | 2800000 | 130 | 16000 | 800 |

| YG-SBB110*8 | 110*1.8*13*8layers*2 | 21.6 | 26000 | 3050000 | 160 | 17600 | 880 |

| YG-SBB80*10 | 80*1.8*16*10layers*2 | 22 | 26400 | 2380000 | 150 | 16000 | 800 |

| YG-SBB100*10 | 100*1.8*16*10layers*2 | 23.3 | 28000 | 3500000 | 165 | 20000 | 1000 |

| YG-SBB110*10 | 110*1.8*16*10layers*2 | 25 | 30000 | 3800000 | 190 | 22000 | 1100 |

Latex Glove Making Machine for Sale:

Characteristics of Latex Gloves Production Line:

- Our factory is designed according to the chemical properties of raw materials and the technical requirements of the glove-forming process. The equipment process is compact and the mechanical structure is more reasonable.

- In order to make the machine achieve the best effect under the minimum power, our drying box adopts the tunnel-type drying method, adopts the principle of hot air rising, and the hot air is recovered to achieve circular mixing.

- Choose a special high-temperature-resistant chain to speed up production and increase production value.

- The principle of hot air circulation in the heated space is used to reduce the cost; in the multi-segment PID temperature intelligent control system, the temperature error does not exceed ± 5 ℃, and the gloss is uniform even when heated.

- Active vibration glue dispensing and uniform glue system make the product gloves have good regularity and thickness uniformity.

- In view of the shortcomings of ceramic molds that are fragile when vibrating, the transport mechanism of the device selects a special guide rail to be stable, reliable, and not blocked, meeting the stability requirements of the transport equipment during operation.

- High output value, universal common joint design, simple operation of changing the mold, speed up the circulation speed.

Nitrile Glove Making Machine for Sale:

Process Technology:

Start to→Immerse nitric acid solution→Cold water shower→Immerse alkali solution→Flushing→Mold cleaning agent→Hand mold cleaning after brush tank→Immersion hot water cleaning→Immerse starch coagulant →Drying starch coagulant→Immersion coagulant→Drying coagulant→Immersion of nitrile latex→Liku 1→Film film drying→Crimping→Dry film dry→Hot water leaching 2→Immersion No. 1 water tank→Immersion chlorine water →Immersion No. 2 water tank→Immersion No. 3 water tank→Immersion No. 4 water tank→Release the mold→End

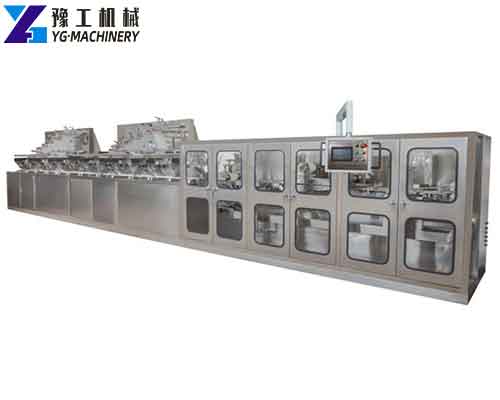

Product Introduction of Nitrile Gloves Production Line:

- Using the most advanced glove production process layout and production process, the product qualification rate reaches more than 98%, and the protein content is less than 120 micrograms/gram.

- TPU coating technology.

- Imported surfactant coagulant, the film formation is more uniform, without powder release.

- With the introduction of a foreign advanced transmission main chain structure, the chain running resistance is small, and the production is stable at high speed.

- The main motor is dragged, which solves the problems of multiple drags, difficult synchronization, many fault points, and difficult maintenance.

- Vertical hot air circulation is adopted in the drying oven, which saves nearly 20% energy consumption compared with other forms of hot air circulation.

- Six-roller long-hair brush mold cleaning technology for cleaning the mold fingers.

- Mold orientation and onboard coding technology.

- Various specifications of the same machine production, automatic curling adjustment, PU curling roller, and long service life.

- Models with different lengths, heights, and costs can be designed according to customer needs.

PVC Glove Making Machine for Sale:

PVC glove production line equipment is the production of synthetic rubber gloves using PVC as raw material through impregnation technology. PVC glove production line equipment mainly consists of four parts: batching equipment, including mixer, filter barrel, vacuum defoaming machine, glue delivery pump; impregnation equipment, Including rack, conveying chain, dipping tank, recovery tank machine, dripping tank; plasticizing furnace; cooling, lip curling, dusting, demoulding, powdering equipment, including cooling group, lip group, powdering group, demolding Group, powder removal group. The production line of PVC gloves adopts continuous production mode and direct dipping mode. The film formation is uniform and the color is gorgeous. Various models and specifications can be produced online at the same time. The production line has a length of 60 meters, 80 meters, and 100 meters, and other specifications. It has high automation and large output. It can be configured with automatic demoulding, and the length of the production line can be designed and installed according to the customer’s production site.

Production Process:

- Impregnation: The hand mold is impregnated in the original liquid in an orderly manner.

- Lip curl: Use a moderate and subtle angle to make a curl on the cuff of the glove.

- Release: Workers quickly and orderly remove the completed gloves from the hand mold.

- Packaging: After physical inspection and visual inspection, various types of packaging are.

Glove Making Machine Price – YG Machinery Manufacturer

The types of production lines are divided into product production lines and component production lines according to the size of the range, according to the pace of pace into pipeline production lines and non-pipeline production lines, according to the degree of automation, divided into automated production lines and non-automatic production lines.

The technological route and labor ratio of the main products or most products of the production line determine that a production line has the necessary equipment to complete the processing tasks of a certain other product, the separation of the equipment, and the layout of the workplace. The most challenging can meet the needs of multi-variety production; under the condition that flow production cannot be used, the organizational production line is a relatively advanced form of production organization; in enterprises with low production output and insufficient machinery and equipment, the production line can be used Obtain good economic benefits.

In YG Machinery, there are many types of production lines, such as mask-making machines, melt-blown cloth production lines, wet wipes machines, woven bag production lines, industrial oxygen generators, PSA nitrogen generators, cryogenic air separation plants, disposable cup making machines, shoe cover making machines, surgical cap making machines, disposable slipper machines, diaper making machines, sanitary napkin making machines, etc. If you are interested in the machine, please contact us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

![]()