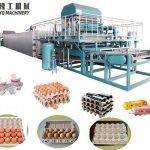

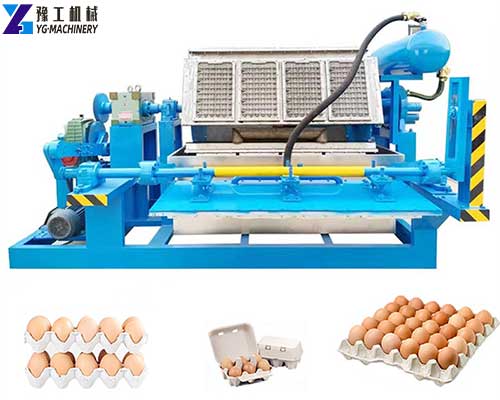

Egg trays generally refer to packaging tools used to hold eggs such as chicken eggs and duck eggs. Their main function is to reduce shock and facilitate transportation and carrying. According to the different materials used, they can be divided into pulp egg trays, plastic egg trays, etc. According to the number of eggs, they can be divided into egg boxes and tray egg trays. Today we mainly learn about the egg carton machine that makes pulp egg trays.

YG egg carton machine (pulp molding machine) consumes used waste paper as raw material. It produces different kinds of paper trays according to your requirements, such as egg trays/dishes, egg cartons/boxes, fruit trays, industrial package trays, seeding trays, win trays, shoe supports, small product packages, etc. Your market choice decides the different final products.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Parameter of YG Egg Tray-Making Machine:

| Model | YG-1*3 | YG-1*4 | YG-3*4 | YG-4*4 | YG-4*8 | YG-5*8 | YG-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kW) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

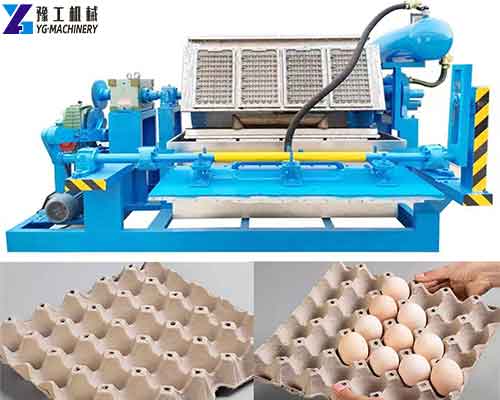

Raw Material

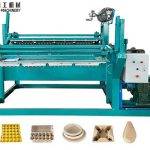

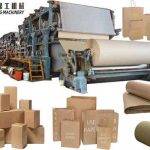

Pulp molding equipment uses waste book paper, waste newspapers, waste cartons, waste scraps from printing and packaging plants, and tailings from paper mills as raw materials to produce and process various degradable egg trays, egg boxes, shoe linings, and paper trays for electronic product inner packaging. The production steps are beating-molding-dehydration-drying-packaging.

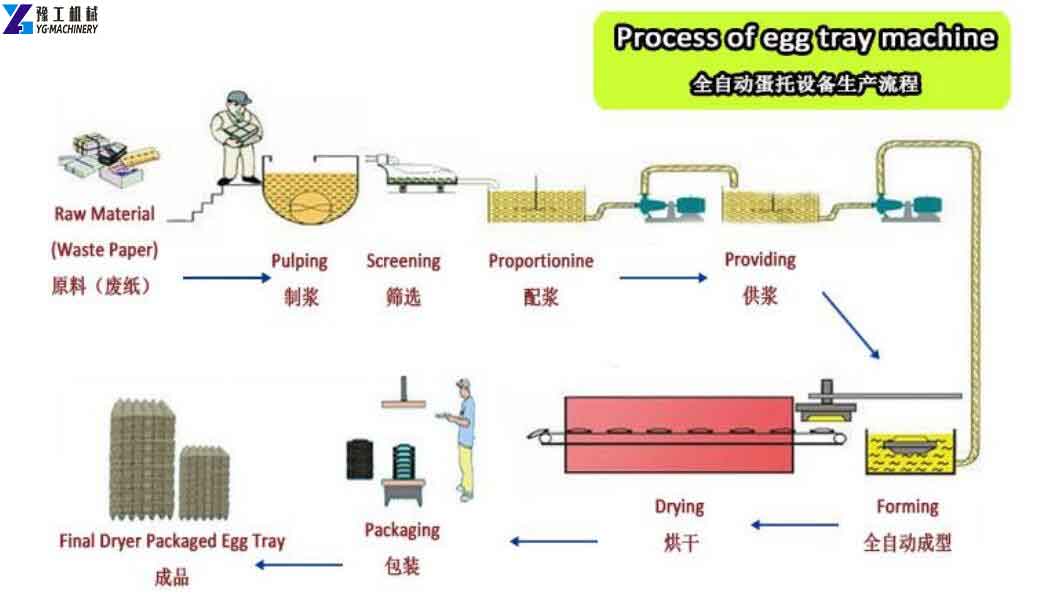

Overview of the Egg Tray Production Process

- Automatic status: Fully automatic production line, only raw materials must be put in, products are packaged, and pulping, forming, drying and stacking are all completed automatically.

- Production: 1000-6000/piece.

- Required operators: 1 person in the pulping area, 1 person in the forming area, 1 person for packing after stacking, 1 person for warehouse transfer, a total of 4 people/shift.

- Recommended plant size: 50*18 meters, height above 5 meters, adjusted according to the customer’s existing factory.

- Installation and commissioning: We send engineers to the buyer for guidance, installation, commissioning, and training.

- Warranty period: 1-year warranty for the whole machine, 3 years warranty for the machinery and main structure.

FAQ About the Egg Carton Machine:

Q: What is the weight of the wet and dry egg tray?

A: The weight of wet egg tray products ranges from 200g to 350g; the weight of dry is generally 80-100g. It can be adjusted by adding auxiliary agents according to customer needs.

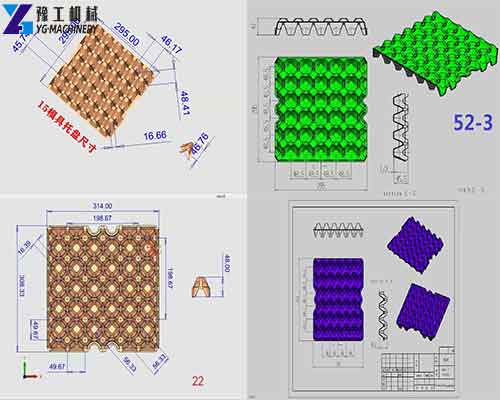

Q: What is the difference between aluminum molds and plastic molds?

A: Aluminum molds have a long service life, and plastic molds are cost-effective.

Q: Can equipment export services be provided?

A: Our equipment has been sold to more than 100 countries in many regions worldwide. We have rich export experience and can provide customers with equipment and export services throughout the process. At the same time, we have multilingual business personnel and after-sales technical engineers in English, Russian, Spanish, Indonesian, Japanese, Korean, etc., which can facilitate communication and exchange.

Q: Does it support customized colors and logos?

A: Yes, our equipment can be customized according to customer requirements, including topcoat color and corporate logos.

Q: How long does it take to dry and how big a drying area is needed?

A: If the temperature is around 30 degrees, it takes 6-7 hours to dry; if the temperature is around 40 degrees, it takes about 4-5 hours; taking egg trays as an example, with a production of 1,000 pieces, at least 500 square meters of drying area is needed.

Egg Carton Machine Manufacturer – YG Machinery

The egg carton machine is made of waste paper, which can make 6-shell egg boxes, 12-shell egg crates, etc. It can be customized according to your requirements. More than that, the YG egg tray production line employs an automatic pulp molding system, which makes it easy and safe to operate. We have exported our egg carton-making machine to Spain, Ghana, the United States, Mexico, Zimbabwe, Thailand, Russia, Vietnam, South Africa, etc. YG Machinery will offer you a high-quality egg tray-making machine and the spare parts you need. Welcome to contact us!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800