Whether searching for clean underground water sources, extracting precious mineral resources, or laying solid foundations for skyscrapers, all grand engineering projects begin with the exploration of the underground. However, the underground world is far more complex than the surface—hard granite, soft sand layers, high-pressure groundwater, and the ever-present threat of sinkholes all pose severe challenges to the stability and penetration capabilities of drilling equipment. Traditional, simple drilling rigs often become ineffective after reaching a certain depth, wasting valuable time and increasing project risks and costs.

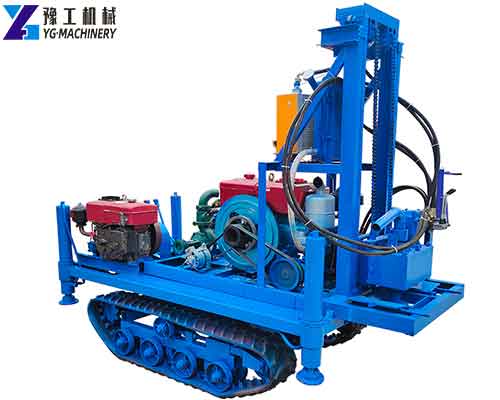

How can one possess a drilling tool that can stably, efficiently, and safely penetrate various complex strata to reach the target depth? This is a core pain point that all engineering contractors and geological exploration companies must address. YG drilling rig machines are designed specifically to meet these challenges. Our equipment perfectly combines powerful hydraulic power, high-strength materials, and a precise drilling control system. This means that whether your project is in rugged mountains, deep in the desert, or on a crowded urban construction site, YG’s drilling rigs provide stable power output and excellent drilling performance, ensuring you can accurately and efficiently obtain geological data or complete engineering boreholes. Choosing YG means choosing the key force to overcome depth and geological limitations and ensure the smooth progress of your project. Contact us now to learn about different types of drilling rigs and their pricing. We can also recommend the most suitable equipment for your project needs.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Why Choose a YG Drilling Rig Machine?

- High-Efficiency Power System: Utilizes an internationally renowned diesel engine, ensuring stable and powerful power output even in remote areas.

- Fully Hydraulic Control: Drilling, lifting, slewing, and outrigger functions are all fully hydraulically controlled, ensuring smooth and precise operation and significantly reducing the failure rate.

- Multi-functional Mast Design: The mast design allows for large-angle inclined drilling and long-stroke drilling, improving the rig’s operational flexibility.

- Environmentally Friendly and Energy-Saving: Optimized power transmission system reduces energy consumption and is equipped with efficient noise and vibration reduction devices, meeting the latest global environmental standards.

How to Choose the Right Drilling Rig Machine?

- Target Geological Conditions: Is it soft soil, sand, or hard granite? This will directly determine whether you need a mud rotary drill or a down-the-hole percussion drill.

- Hole Diameter and Depth Requirements: The deeper and larger the borehole, the higher the requirements for the drilling rig’s lifting force, torque, and hydraulic system. A larger tonnage and more specialized drilling rig model must be selected.

- Site Environment and Mobility: If operation is required in rugged mountainous terrain or confined spaces, tracked or small vehicle-mounted drilling rigs should be prioritized to ensure rapid arrival and deployment capabilities.

![]()