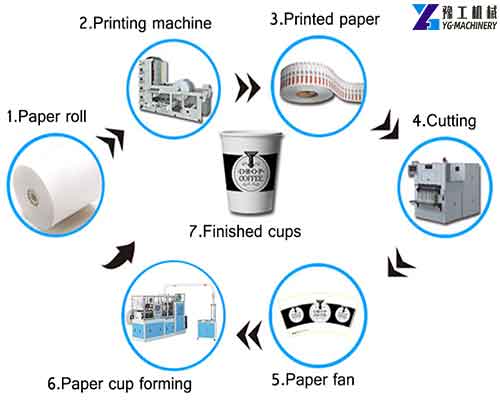

Our double wall paper cup sleeve forming machine is for noodle cups and high-quality coffee cups. It can be used with paper cup making machines. The paper cup sleeve machine is designed for the subsequent processing of double-wall paper cups. Its function is to perfectly combine the printed paper blank with paper cups. The outer layer of paper may play a role in thermal insulation and improve the strength and aesthetic properties of the paper cup body. Contact us to know the machine price now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Double Wall Paper Cup Machine Technical Parameter:

| Model | YG-35 |

| Paper Cup Size | 3-16oz |

| Paper Cup Top Diameter | Min 65mm-max94mm |

| Paper Cup Bottom Diameter | Min45mm-60mm |

| Paper Cup Height | Min60mm-135mm |

| Raw Material | PE-COATED PAPER.RIPPLE PAPER ETC |

| Speed | 80-90pcs/min |

| Speed of 20 hours of stable running per day | |

| Suitable paper weight | 150-350gsm |

| Voltage supply | 220v50hz single phase/ 380v50hz 3-phase

(better to use 380v50hz 3-phase) *If the user’s voltage supply is different, please inform us in advance. |

| General power | 4.7KW |

| Net weight | 1500kgs |

| Measurement (mm) | 2150*950*1650MM |

| Cup Side Sealing | Ultrasonic |

| We can customize the machine and mold according to the customer’s requirements. | |

7 Main Features of Double Wall Paper Cup Machine:

- Output is improved: our machine can reach 80-90pcs/min.

- A stepping motor is used to control the bottom paper feeding so that the gap between the bottom paper is controlled within 0.1mm, which can make the machine more stable and save raw material. With light eyes under the paper roll, the machine will be stopped when out of bottom paper, avoiding waste in the paper.

- A gear drive is adopted to avoid the defect of the loose gap of the chain drive.

- We use a self-lubrication system in the machine, which reduces the friction between the parts. So the machine can be maintained without manually fueling.

- This device adopts a non-contact multi-point light control switch (such as in a paper holder, glass tube, bottom paper, and so on, according to customer demand). It can detect the working situations, then achieve a fault alarm preventing the machine from collision, making the machine more stable and longevous.

- The paper tube station uses an independent cam to handle the glass holder. This is advanced instability and will not make noise when it works.

- The machine is equipped with a gear motor simplifies the complicated system and makes the machine more stable.

Double Wall Paper Cup Machine Price – YG Machinery Manufacturer