Core drill rigs are a kind of machine that can be usually used to drill holes in the earth’s subsurface. For its different uses, we can divide the machine into exploration core drilling equipment, core sample drilling equipment, core drilling machine for mining, and water well drilling rigs. In general, a core drilling machine always has multiple uses, such as drilling water, geological prospecting, engineering construction and sampling of underground deposits, blasting holes, etc… However, different models vary in the geology they are suitable for, depth of drilling, and opening hole diameter. Meanwhile, the core drill bit is an important part of the core drill rig which needs to be suitable for the geological condition of exploration. So many kinds of core drill rigs for sale in YG Machinery can meet a variety of customer needs. Refer to the technological parameters of each model to choose the one you want or tell us more about your requirements, we will send you the quotation or recommend the most suitable type very quickly.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Types of Core Drill Rig for Sale:

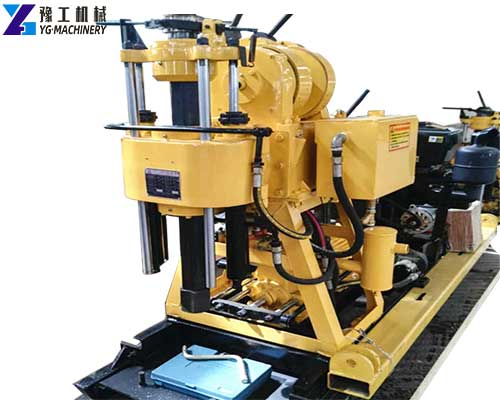

Hydraulic Core Drilling Rig Machine

The hydraulic drilling machine is the most popular type of rig around the world. It adopts an oil pressure automatic feed structure which can greatly improve the efficiency of drilling and reduce the labor intensity of workers, saving time and labor at the same time. There are a variety of hydraulic core drill rigs for sale in our company, such as the HZ series drilling rig, XY-3 series spindle drilling machine, etc… They all have wide uses, including drilling water wells, geological exploration, and some other drilling process requirements. Choose a suitable model according to your requirements now.

Spindle Type Core Drilling Rig

The XY-3 series core drilling equipment, including XYX-3 trailer-mounted drilling rig, XYD-3 crawler-mounted core drilling rig, XYC-200A tricycle-mounted core drill rig machine, and XYC-200GT, XYC-3 truck-mounted core drilling rig are all spindle core drilling equipment. But they have their unique characteristics. Please refer to the respective technical parameters to select the model you need.

The Widely Used Core Drill Rig:

- Water well drilling. The water well drilling rigs for sale in our company have always been the most popular equipment with the largest production volume and sales, which is suitable not only for drilling water wells, agricultural irrigation wells, and ground source heat pump wells but also for water intake projects in mountainous areas and rock formations. If you are looking for this kind of machine, you can go to the page special for a water well drilling machine to select the appropriate model.

- Geological exploration is the very important use of core drill rigs, which includes the exploration of coal fields, petroleum, metallurgy, mineral, and nuclear industries. Here in our factory, you can find drilling rigs with a drilling depth from tens of meters to thousands of meters.

- Sample subsurface mineral deposits. People sometimes call the rig with this function sampling drill rig. The machine with impact and rotary mode has strong adaptability that can be used for various geological situations and different depth sampling.

- Test rock, soil, and groundwater physical properties. The core drilling machine can carry out the underground sampling from shallow to deep, helping to detect the hardness of the rock, soil texture, and the stratification below the surface.

Tips Operators Need to Note When Installing A Core Drilling Rig:

- Please check the roadway support and ventilation first before entering the installation site. Solve the problem found in time. Clean up the surrounding debris when repairing and reinforcing the drill site.

- The drill site area must be larger than the drill base with adequate safety clearance around it.

- The rig should be installed firmly, the oil level in the transmission and mailbox shall be appropriate and the safety cover and protective cover should be complete.

- The operation handle of each part should be in the right position.

- When debugging the machine, the rotating parts are required to operate normally and the switch is flexible and reliable. After confirming that there is no problem, operators can connect the drill pipes and drill bits and start operating the core drilling machine.

The Installation of Drill Pipe and Core Drill Bits:

- Check the drill pipe first. If there is a blockage or bend and the orifice is worn, please replace the drill pipe.

- Please aim at the wire mouth to avoid skew when connecting the drill pipe.

- When loading and uploading the drill pipe, it should be strictly prevented that the pipe pliers hurt the carbide sheet and clip the flat drill bit and core pipe.

- The second drill pipe must be installed after the first one is installed.

- When the bit is fed into the hole, the pressure should be light, not too high, and drill slowly, to break the blade or break the transmission gear. Increase the pressure gradually after the drill bit goes down to the bottom of the hole.

How to Use A Core Drill?

- If the speed of the drill is mechanically adjusted, please don’t change the speed under normal circumstances. If the speed needs to be adjusted, please cut off the power first and the transmission must stop.

- Construction should be carried out strictly according to the orientation, angle, drilling depth, and hole spacing specified in the construction measures when drilling holes.

- When the drilling is carried out with clean water or compressed air, the water supply or supply air must be provided before drilling, and ensure there is sufficient water flow and counter-air volume.

- The residual ruler of the drill pipe shall be measured in time and recorded carefully after the drill hole is opened. In the construction process, record the hole depth after each pipe is drilled.

- The drilling can’t be continued until the processing is correct if there is any abnormality in the hole during drilling.

- When the drilling work stops temporarily, the drill bit should be returned to a certain distance from the bottom of the hole to prevent the drilling pipe from being stuck by coal dust. The drill pipe should be pulled out when the time is more than 8 hours.

- In the drilling process, choose the appropriate bit pressure and drilling speed to feed evenly according to the geological conditions. When drilling in places where the geology is not uniform or where the rock strata meet, the drill pressure and speed should be reduced and the feed rate should be slowed down.

Core Drilling Rig Manufacturer – YG Machinery

When you have the idea of buying a core drill rig for sale, you will certainly take various approaches to find the most suitable machine for you. You can find local sellers, check out information about the core drilling machine, or search for rig machine keywords on Google. No matter which way you use it, a large number of suppliers will appear in your database. Then you need to choose the suppliers carefully, for that there are probably a lot of middlemen who will give you a higher price. You will send inquiries to the suppliers you selected which must contain our company – Henan YG Machinery because we are always in the lead. Then congratulations, you have found reliable and professional core drilling rig manufacturers! And we will have a very pleasant cooperation.

Why Buy Core Drill Rig for Sale in YG Machinery?

- Professional manufacturer. Firstly, we have specialized in the manufacturing of drilling rigs for more than twenty years with 150 acres of factory space and over 200 staff now. Secondly, to maintain the leading level in this field, we continuously introduce advanced technology and production equipment.

- Machines radiate to a wide range of countries. With the continuous development and expansion of our company, a special foreign department was established several years ago. Now our drilling rigs have been exported to many countries around the world, such as Russia, America, Indonesia, India, Vietnam, Germany, Pakistan, Bangladesh, Australia, Mexico, Sri Lanka, Honduras, South Africa, Kenya, Ghana, Norway, etc…

- Excellent quality. We use the best production materials and the most advanced system structure which makes our machine more automatic and more efficient. Meanwhile, they always have a longer service life.

- Various types for different uses. From small sizes to large sizes, our core drill rigs can drill holes of different depths and are suitable for both soft soil and hard rock.

- Competitive price and low maintenance cost. First, the drilling rigs are sold directly by the manufacturer, so the price is relatively lower than the same equipment sold elsewhere. Second, our machine isn’t easy to damage as long as the operators follow our operating procedures which can save a lot of maintenance costs.