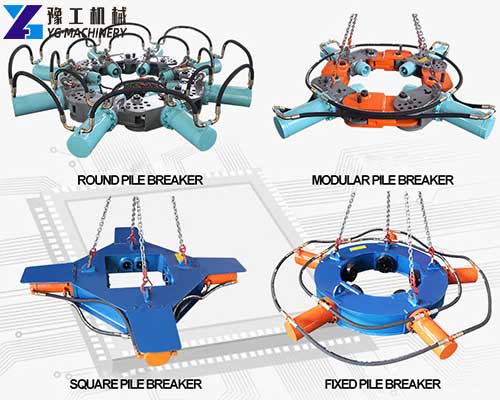

Excavator hydraulic shears are used to cut scrap steel and industrial demolition, also called demolition shears. This is a new scrap steel shearing product, which is relatively strong in the market in terms of shearing force and strength. This type of scissors is suitable for different operations, including the demolition of steel structures, and the processing of scrap steel. If you want to know more, you can contact us at any time! In addition, we also have concrete pile breakers that can be suitable for excavator machines. 【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Excavator Hydraulic Shearing Machines Parameter:

| Product | Excavator-mounted hydraulic demolition shear for waster scrap rebar | ||||

| Item | YG-620 | YG-1413 | YG-2200 | YG-2977 | YG-4052 |

| Weight kg | 620 | 1413 | 2200 | 2977 | 4052 |

| Max. Open Size mm | 334.4 | 540 | 500 | 660 | 801 |

| Width mm | 864 | 1175 | 1370 | 1600 | 1700 |

| Height mm | 1521 | 2050 | 2380 | 2600 | 2700 |

| Effective Shear Depth mm | 286 | 348 | 486 | 578 | 736 |

| Rotating Way | 360 collision | 360 hydraulic | |||

| Working Pressure Bar | 235 | 300 | 320 | 320 | 320 |

| Bottom Shear Force T | 81.2 | 138.2 | 171.2 | 330.2 | 387.2 |

| Medium Shear Force T | 50.2 | 80.2 | 100.2 | 189.2 | 218.2 |

| Tip Shear Force T | 32.2 | 53.2 | 75.2 | 127.2 | 147.2 |

| Applied Excavator Weight T | 5-9 | 10-19 | 20-25 | 28-35 | 38-50 |

Working Principle of Scrap Metal Shear for Excavator:

The olecranon can be rotated 360°, shrouded in a heavy-duty pivot design, strong structure, and long-term wear resistance. The blade seat of the olecranon has high strength and can also provide good shear resistance. At the same time, the blade can be easily replaced and does not require a grinding and welding process.

The jaw size of the olecranon and the special blade design can improve the production capacity of the machine. All the rotary olecranon series can quickly and easily replace the blade, so it can effectively reduce the downtime of mechanical failure and optimize productivity. The powerful hydraulic cylinder can effectively strengthen the closing force of the jaws, which can shorten the corresponding steel. The rotary olecranon series products can be made of high-grade steel to ensure the strong strength of the tool. And very good anti-wear properties.

Product Advantages of Excavator Hydraulic Shearing Machine:

- The closed steel plate structure eliminates and reduces any side twisting or bending deformation.

- The special blade design improves productivity and facilitates blade replacement, which can reduce machine downtime and optimize productivity.

- The enlarged hydraulic cylinder greatly strengthens the closing force of the jaws to cut the hard steel.

- The product is made of high-grade steel, corrosion-resistant treatment, and waterproof design, which ensure the strength and wear resistance of the tool.

The installation of hydraulic shears is simple. Connect the pinhole with the pinhole on the front end of the excavator, and connect the pipe on the excavator with the hydraulic shear use, which is convenient for alternate use between attachments. Olecranon shears look for YG Machinery, hydraulic shears can be installed on various brands of excavators, and only one operator of the excavator is required to operate it, which truly realizes the versatility and economy of the product.

Application Range of Scrap Metal Shear for Excavator:

It is mainly used for the dismantling of chemical plants, steel mills, and steel structure plants. It has the characteristics of safety, convenience, and high efficiency. When the scrap is recycled and decomposed, the larger scrap is cut into pieces and packaged. A scrap steel shearing machine can reduce at least 7-9 workloads, greatly improve work efficiency, and avoid manual safety problems. It can be applied to scrap metal recycling companies. The product is designed with more functions and can meet different needs without using other machines. The powerful and optimized dynamic design ensures sufficient power, saves operating time, and improves production efficiency. The use of a high-quality wear-resistant material structure prolongs the service life of the product and reduces equipment downtime.

Excavator Hydraulic Shears Manufacturer – YG Machinery

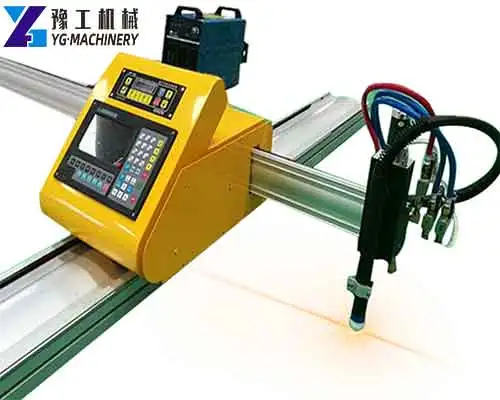

Excavator hydraulic shears can be equipped with various brands of excavators according to the site conditions, which can indeed reduce product costs and make them versatile, which can be applied to different environments. The construction personnel does not touch the construction and adapt to the requirements of complex terrain construction. In addition, YG Machinery has other types of cutting and demolition equipment, such as concrete pile cutters, concrete wall saw machines, diamond wire saw machines, hydraulic rock splitters, high-frequency wall saws, mini spider cranes, excavator rock splitters, hydraulic breaker machines, excavator drum cutters, excavator crusher buckets, excavator rock saws, excavator drill and splitting machines, mobile crushers, firewood splitter machines, horizontal band saw machines, etc. Contact us to learn more about machines!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800