The spray cannon machine is an environmentally friendly device developed to reduce dust in the air. Spray cannon, which can also be called a fog cannon, dust control fog cannon, water fog cannon, or fog cannon sprayer is a professional dust control removal equipment. It has a spray system, which has a certain control effect on dust suppression, reduces the large particle content in the air, and has a limited effect on tiny particles. In addition, we also have other engineering construction machinery, mortar spraying machines, shotcrete sprayers, hydroseeding machines, sandblasting machines, GRC machines, mini concrete pumps, mini excavators, etc. Contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Technical Parameter of the Fog Cannon Machine:

| Model | YG-20 | YG-30 | YG-40 | YG-60 |

| Spraying distance | 20m | 30m | 40m | 60m |

| Engine | electric | electric | electric | electric |

| Electric | 380V/50HZ,3 phase | 380V/50HZ,3 phase | 380V/50HZ,3 phase | 380V/50HZ,3 phase |

| Fan motor | 3kw | 3kw | 4kw | 11kw |

| Steering motor | 2*1.5kw | 2*1.5kw | 2*1.5kw | 2*1.5kw |

| Pump motor | 1.5kw | 1.5kw | 2.5kw | 7.5kw |

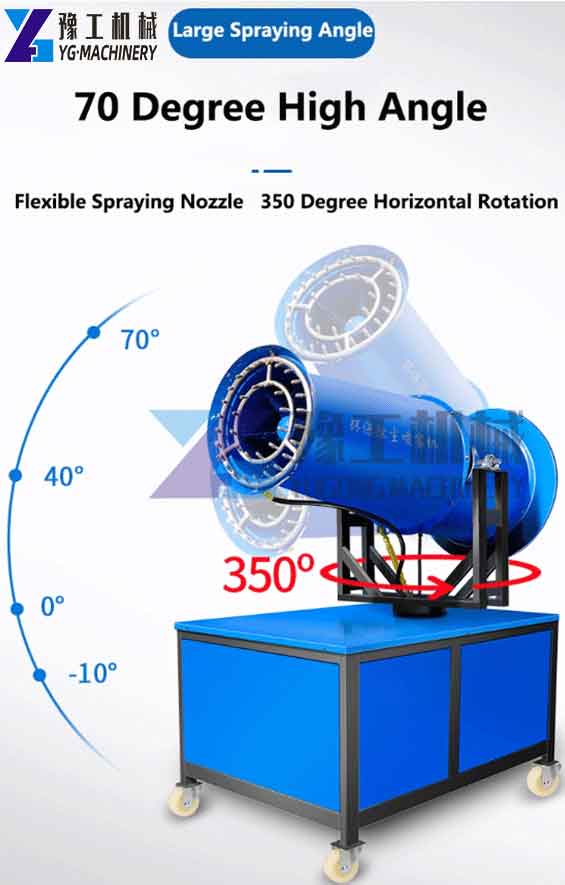

| Horizontal angle | 360° | 360° | 360° | 360° |

| Vertical angle | Minus10°-55° | Minus10°-55° | Minus10°-55° | Minus10°-55° |

| The nozzle | 8 | 10 | 16 | 22 |

| Cylinder material | Q235 Carbon steel | Q235 Carbon steel | Q235 Carbon steel | Q235 Carbon steel |

| Bucket | 460L | 480L | 800L | |

| Water consumption | 1000L/h | 1500L/h | 3000L/h | 7500L/h |

| Recycled water pipe | 1400mm | 1400mm | 1400mm | 1400mm |

| The machine size | 1170*940*1700mm | 1170*940*1800mm | 1650*1200*2200mm | 1700*1200*2200mm |

| Weight | 200kg | 250kg | 300kg | 350kg |

The Working Principle of the Spray Cannon Machine:

According to the theory of liquid atomization and air jet, the spray cannon machine first uses a high-pressure pump to pressurize the liquid, then atomizes the water through a micro atomizing nozzle, and then uses the high air volume and high wind pressure of the high-pressure jet fan to atomize the atomized the water mist is sent to a long distance so that the water mist can reach a larger area while covering a larger area. During this process, the dust particles and the water mist particles are in full contact and become wet, and the wet dust particles continue to adsorb other dust particles and gradually condense into pellets, and then the dust particles settle due to their gravity, thereby achieving the intended the effect of dust and dust reduction reduces the concentration of PM2.5 in the air and improves the air quality.

Fog Cannon Application Areas:

The spray cannon machine is suitable for dust removal on construction sites, dust removal in workshops, dusting of road vehicles, large gardens, greening trees, road forests, lawns, etc., such as spray humidification, coal yards, power plants, steel slag yards, iron ore yards, loading and unloading yards, railway freight yards, urban roads, and prevention of pests and diseases can also be applied to environmental protection industries, dust-prone coal and other material storage yards, such as dust, dust suppression, and cooling.

The Main Structure Consists of Spray Cannon:

Water tank, water pipe, plunger pump, nozzle, fan, generator set ( gasoline or diesel ), horizontal steering device, vertical pitch device, electric control box, remote control, etc.

6 Features of the Spray Cannon Machine:

- Long-range, strong penetrability, wide-coverage, fine mist particles, more uniform spray, fast dust reduction, and higher work efficiency.

- The PLC-integrated intelligent control cabinet can achieve quantitative, timing, and fixed-point spray.

- The supporting power is flexible, the 380V mains can be used, and the generator set can also be supplied with power.

- It can be installed on a concrete platform or steel frame platform, or it can be installed on vehicles.

- With a variety of operating models, reliable operation, and precise control within 100 meters of the remote control.

- Water-saving and energy-saving, the water consumption can be saved by 70%-80% compared with other dust suppression spraying equipment (spraying spray gun, watering locomotive), and the water mist coverage area is much larger than other spraying equipment.

Spray Cannon Machine Safety Procedures:

- When working, strictly follow the operating procedures. It is strictly forbidden to press the pump start button first. The pump must be started after the fog gun machine is running normally, so as not to cause the liquid to flow back to the fan and the spray tube by starting the pump first.

- After the fan is running, the person should not be near the air inlet of the fan or stand at the exit of the air duct. It is forbidden to stand or place debris within 1 meter of the air inlet direction. It is forbidden to stand in the direction of 5 meters. When there is wind, spray it in the wind.

- It is strictly forbidden to enter the water tank with mud and debris, to avoid blocking the pipeline, the nozzle of the fog gun machine, or damaging the water pump; if the nozzle is blocked or leaking, it should be shut down and cleaned up in time.

- Check the tightness of the screws in each part. It is forbidden to dry the pump without water, so as not to burn the parts inside the machine. During the operation of the machine, it is strictly forbidden to contact the various parts of the body for power rotation and transmission components.

- After the end of winter work, water must be drained from the machine; when not in use, the water in the machine must be completely drained to avoid cracking equipment and pipes.

- When the temperature reaches the freezing point or the machine is frozen, it is strictly forbidden to start the machine. Otherwise, the fog gun machine can’t rotate and burn the equipment or other accidents. If it needs to be used, it must melt the ice inside the machine. The device can only be started.