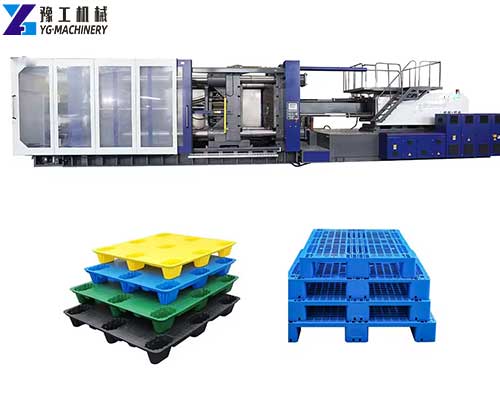

Plastic pallet injection molding machine is a kind of injection molding equipment specially used for producing plastic pallets. It heats the molten plastic and then injects it into the mold cavity under high pressure. After cooling and solidification, it forms a plastic pallet with a specific shape. This molding method has the advantages of high production efficiency, stable product quality, and precise size. It is widely used in logistics, warehousing, manufacturing, and other industries. Do you also need a plastic injection molding machine to improve your work efficiency? Contact us.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Plastic Pallet Injection Molding Machine Parameter:

| Model | YG-1500L-1 | YG-1500L-2 |

| Pallet Blow Molding Machine | One layer | Two layers |

| Max. Product Size | 9*4.5*5.2m | 9*5*5.2m |

| Machine Dimension | 32ton | 36ton |

| Total Power | 200kw | 287kw |

| Average Power Consumption | 100kw | 130kw |

| Accumulator Die Head | ||

| Accumulator Capacity | 45L 33kg | 45L 33kg |

| Heating Load | 50kw | 60kw |

| Extrusion System | ||

| Screw Diameter | 150mm | 110/110mm |

| LD Ratio | 30:1 | 30:1 |

| Extruder Motor Power | 20kw | 90kw/90kw |

| Heating Power | 30kw | 60kw |

| Plasticizing Capacity | 300kg/h | 350kg/h |

| Mold Clamping Unit | ||

| Clamping Platen Size | 1600x1700x76mm(customized) | 1600x1700x76mm(customized) |

| Max Mold Size | 1200x1800mm | 1200x1800mm |

| Clamping Force | 1200KN | 1200KN |

| Hydraulic System | ||

| Main Oil Pump Power | 36kw | 36kw |

| Small Oil Pump Power | 7.5kw | 7.5kw |

| Oil Tank Capacity | 1000L | 1000L |

Structure and Working Principles of Plastic Tray Injection Molding Machine:

The plastic tray molding machine is mainly composed of the following parts:

- Injection system: including hopper, screw, barrel, etc., responsible for heating and melting plastic particles and injecting them into the mold under high pressure.

- Mold closing system: composed of movable platen and fixed platen, responsible for closing the mold to ensure the molding of plastic parts.

- The cooling system accelerates plastic parts’ cooling and solidification by circulating water or oil.

- Hydraulic system: provides hydraulic power required to drive injection, mold closing, and other actions.

- Control system: controls the entire injection molding process to achieve automated production.

Working principle of plastic pallet machine:

- Plasticization: Plastic particles are heated and melted in the barrel and pushed forward by the screw.

- Injection: Molten plastic is injected into the mold cavity under high pressure.

- Pressure holding: maintain a certain pressure to ensure that the plastic parts fill the mold.

- Cooling: The plastic parts are cooled and solidified in the mold.

- Mold opening: The mold is opened and the plastic parts are taken out.

Features of Plastic Pallets:

- Corrosion-resistant and easy to clean: Plastic pallets are not easy to rust, are acid and alkali-resistant, have a smooth surface, are easy to clean and disinfect, and are particularly suitable for food, medicine, and other industries.

- Lightweight and high strength: Compared with wooden or metal pallets, plastic pallets are light and easy to carry, while having high load-bearing capacity and impact resistance.

- Various sizes and customizable: Plastic pallets can be customized in size, shape, and color according to different needs to meet multiple logistics scenarios.

- Long service life: Plastic pallets are wear-resistant and durable, have a long service life, can be recycled, and reduce resource waste.

Application Cases in Different Industries of Plastic Pallet Machines:

Automobile manufacturing:

Developed countries such as Germany and Japan: The production of auto parts requires extremely high precision and efficiency. Plastic pallet machines are widely used in the transportation, assembly, and storage of auto parts. For example, German automakers such as BMW and Volkswagen use plastic pallet machines to realize the automated transportation of large parts such as automobile chassis and engines to improve production efficiency.

Food and beverage industry:

Countries such as the United States and Europe: The food and beverage industry has strict requirements on hygiene and safety. Plastic pallet machines play an important role in food production, packaging, and distribution. For example, the Coca-Cola Company in the United States uses plastic pallet machines to realize the automated packaging and palletizing of beverage bottles, which improves production efficiency while ensuring the hygiene and safety of products.

Electronic manufacturing industry:

Countries such as China and South Korea: Electronic products are updated quickly and require high production flexibility. Plastic pallet machines play an important role in the transportation, assembly, and storage of electronic components. For example, electronic manufacturing companies such as Foxconn in China use plastic pallet machines to achieve small-batch and multi-variety production of electronic components to meet market demand.

Logistics industry:

Global scope: The logistics industry has high requirements for efficiency and cost control. Plastic pallet machines play an important role in the warehousing, outbound, and sorting of goods. For example, Amazon and other e-commerce giants in the United States use plastic pallet machines to achieve warehouse automation and improve order processing efficiency.

Advantages of Plastic Pallet Machines in Different Application Scenarios:

- Improve production efficiency: Automated conveying, stacking, and de-stacking, reduce manual operations, and improve production efficiency.

- Improve product quality: Accurately control the conveying speed and position, reduce product damage, and improve product quality.

- Reduce production costs: Reduce labor costs, improve resource utilization, and reduce production costs.

- Improve working environment: Reduce the labor intensity of workers and improve the working environment.

- Improve storage efficiency: Achieve high-density storage and improve storage utilization.

Plastic Pallet Injection Molding Machine Price – YG Machinery

Plastic pallet injection molding machines are widely used in many industries such as food, medicine, electronics, etc., providing efficient and reliable logistics solutions for these industries. Plastic pallet injection molding machines can not only efficiently produce high-quality plastic pallets but also achieve low carbonization of the production process by adopting environmentally friendly materials and optimizing processes. This makes plastic pallet injection molding technology play a positive role in promoting the development of green logistics. If your project or industry requires an injection molding machine, feel free to contact me for a quote.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

![]()