As a highly automated and efficient food processing equipment, the hard candy production line plays a vital role in the candy manufacturing industry. Its application range is wide, not only limited to the production of traditional hard candy but also can be extended to other candy products. According to your different needs, we have a hard candy depositing line and a hard candy die-forming line to choose from. Contact us now!【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800

Hard Candy Production Line Parameter:

| Model | YG-150 | YG-300 | YG- 450 | YG-600 |

| Hard candy weight |

According to the candy type |

|||

| Depositing speed | 50-70n/min | 50-70n/min | 50-70n/min | 50-70n/min |

| Steam requirements | 250kg/h,05-0.6MPa | 300kg/h,05-0.6MPa | 400kg/h,0.5-0.6MPa | 500kg/h,0.5-0.6MPa |

| Compressed air requirements |

0.6m³/min,04-0.6MPa,0.2m³/h |

|||

| Working environment requirements |

Temperature: 20-25℃ Humidify: 55% |

|||

| Machine power | 18KW/380V | 27KW/380V | 34KW/380V | 38KW/380V |

| Line length | 17m | 19m | 19m | 22m |

| Machine weight | 3500kg | 4000kg | 4500kg | 5000kg |

| Theoretical output | 150kg/h | 300kg/h | 450kg/h | 600kg/h |

Hard Candy Making Machine Core Application Areas

Hard candy production:

- Traditional hard candies: Hard candies of various shapes such as round, oval, square, etc. can be added with fillers of different flavors and colors.

- Personalized hard candies: Various patterns, LOGOs, etc. can be customized according to customer needs for promotions, gifts, etc.

- Special-function hard candies: These include hard candies with added nutrients, such as vitamins and minerals, or lollipops with special functions.

Other candy products:

- Hard candy: By adjusting the mold and formula, various hard candies can be produced, such as fruit hard candy, mint candy, etc.

- Soft candy: Some soft candy production lines also have the function of producing lollipops.

- Chocolate products: Chocolate bars, chocolate balls, etc. can be produced.

Features and Advantages of Hard Candy Production Line

- High degree of automation: greatly reduces manual operation and improves production efficiency.

- High production efficiency: one production line can produce hard candies of various flavors and shapes at the same time.

- Stable product quality: by precisely controlling production parameters, the stability of product quality is guaranteed.

- Strong flexibility: the production formula and process can be adjusted according to market demand.

- Sanitary and safety: food-grade materials are used to meet food safety standards.

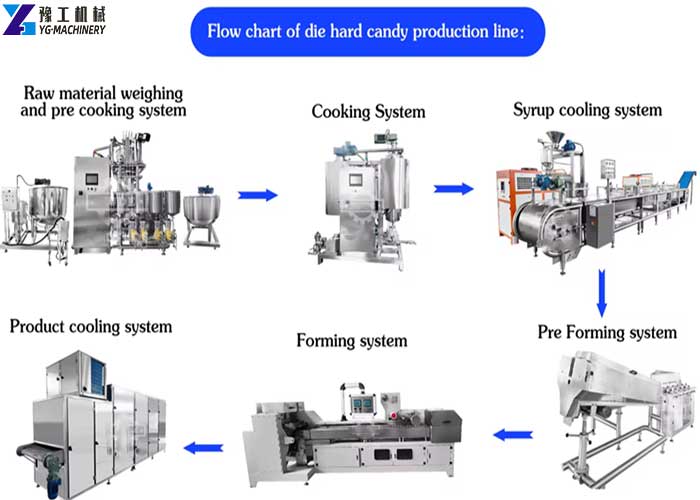

Main Equipment of Hard Candy Production Line

- Ingredients system: Accurately proportion various raw materials, such as sugar, water, spices, and pigments.

- Sugar boiling system: Heat the sugar solution under vacuum or normal pressure to remove moisture and make the sugar solution reach the required concentration.

- Molding system: Pour or stamp the boiled sugar solution into shape to produce hard candies of various shapes.

- Cooling system: Rapidly cool the molded candy to shape it.

- Packaging system: Pack the cooled candy to ensure product hygiene.

Hard Candy Production Process

- Ingredients: According to the formula, accurately weigh sugar, water, spices, and other raw materials and mix them evenly.

- Boil: Put the prepared liquid into the sugar boiling pot, heat it under vacuum or normal pressure, stir it continuously, evaporate the water, and gradually increase the concentration of the sugar solution.

- Molding: Pour or stamp the boiled sugar solution through a mold to produce hard candies of various shapes.

- Cooling: Rapidly cool the molded candy to shape it.

- Packaging: Pack the cooled candy to ensure product hygiene.

Hard Candy Die-forming Line VS Hard Candy Depositing Line

| Project | Die-forming production line | Depositing line |

| Molding method | High-pressure injection | Gravity filling |

| Product shape | Various and complex | Relatively simple |

| Surface smoothness | High | High |

| Hardness | High | Moderate |

| Production efficiency | High | Low |

| Scope of application | Mass production, complex shapes | Small production, special materials |

Hard Candy Production Line Manufacturer – YG Machinery

As the core equipment of the candy manufacturing industry, the hard candy production line has a high degree of automation, high production efficiency, and stable product quality, providing consumers with a variety of hard candy products. With the continuous advancement of technology, the hard candy production line will develop in the direction of intelligence, personalization, and green environmental protection to meet the increasingly diversified needs of consumers. The investment boom in the hard candy production line is the result of multiple factors such as market demand, technological progress, and policy support. With the improvement of people’s living standards and the change in consumption concepts, the hard candy market will continue to maintain a growth trend and bring considerable returns to investors. Why not start this project now? Seize the opportunity to make money.【WhatsApp/WeChat/Skype/Phone】+86 136 1385 6800