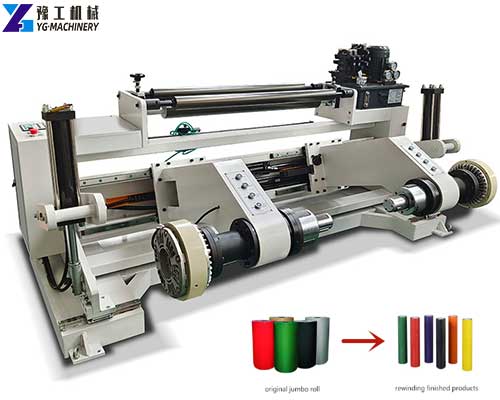

Paper slitting rewinding machine is an important paper processing equipment, which is widely used in printing, packaging, labeling, paper products, and other industries. It can slit wide paper rolls into required widths and rewind them into small rolls to meet the needs of different users. They are used to slit various paper for various purposes as required, such as notebook paper, tissue paper, construction paper, cardboard, tableware, roll paper, magazines, bags, labels, loose paper, etc. In addition, several advantages of this machine such as winding, rewinding, and roll handling machines support product needs. Do you want to know more about the paper slitting machine details? Contact us now!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Paper Slitting Rewinding Machine Parameter:

| Model | YG- 1300 | YG- 1600 | YG- 1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Min width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

Roll Slitter Rewinder Features:

- The machine body is made of 40 thick high-quality steel plates to ensure that the machine will not shake when running at high speed, thereby improving the accuracy of paper roll slitting.

- This machine uses two servo motors, one for material transmission and the other for winding shaft.

- It adopts Siemens PLC, an intelligent operation program system with multiple functions, automatic meter counting, automatic shutdown when winding meters are set, emergency shutdown, etc.

- Automatic tension control. This machine can automatically measure the diameter of the mother roll and automatically adjust the output tension.

- The hydraulic lifting and unwinding structure makes large roll loading and unloading easier and saves labor.

- The finished roll is automatically unloaded to the ground.

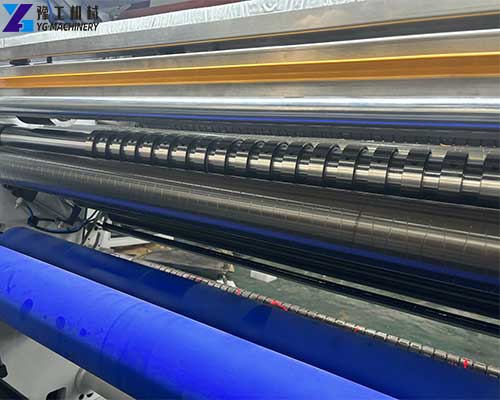

- The deviation correction system automatically detects the edge of the roll and adjusts the position to improve accuracy.

- The slitting knife is installed on the back of the machine. This design makes it more convenient to adjust the knife.

Main Application Areas:

1. Printing industry

Book and magazine printing: Cut large rolls of coated paper into A4 size, etc. to meet the printing needs of books and magazines of different specifications.

Label printing: Cut label paper into small rolls for easy labeling.

2. Packaging industry

Carton production: Cut corrugated paper into different widths for the production of cartons of various specifications.

Paper bag production: Cut kraft paper into the required width for making paper bags.

3. Label industry

Self-adhesive labels: Cut self-adhesive label paper into small rolls for easy labeling.

Self-adhesive labels: Cut self-adhesive label paper into different specifications to meet the labeling needs of different products.

4. Paper products industry

Paper towels, and napkins: Cut the base paper into small pieces for the production of paper towels, napkins, etc.

Cash register paper: Cut thermal paper into small rolls for cash registers.

5. Other industries

Medical industry: Used to produce medical paper products, such as surgical gowns, masks, etc.

Electronics Industry: Used to produce packaging materials for electronic products.

Production Requirements:

- Material types: What types of paper do you need to process? Different types of paper (such as coated paper, corrugated paper, self-adhesive paper, etc.) require different equipment.

- Paper thickness: The thickness of the paper will affect the selection of the slitting knife and the equipment’s power.

- Roll diameter and width: The raw paper roll’s diameter and width determine the equipment’s specifications.

- Cutting width: What widths do you need to slit the paper into?

- Production requirements: What is the daily output of the production line?

Paper Slitting Rewinding Machine Manufacturer – YG Machinery

Paper slitting and rewinding machines play an important role in modern industry. Various packaging, printing, and other industries use this machine to improve production efficiency and reduce costs to expand market share and meet market demand. Choosing a suitable paper slitting and rewinding machine requires comprehensive consideration of multiple factors, including production requirements, equipment performance, configuration, manufacturer services, and price. Of course, Yugong Machinery can also provide you with solutions based on your personal needs and support customized services. Are you interested in the paper slitting rewinding machine now? Contact us.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800