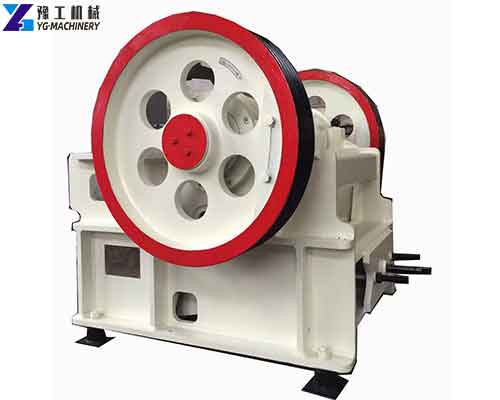

A crusher is a commonly used equipment in mining, construction, and other industries, used to break large pieces of material into smaller particles. According to the crushing principle, structural characteristics, and application range, stone crushers can be divided into many types. We are more exposed to jaw crushers and cone crushers. Today we will first discuss the characteristics of jaw crushers. A jaw crusher, also known as a stone crusher, is a machine that uses extrusion, splitting, bending, and other methods to break large rocks into smaller particles. It is widely used as crushing equipment in mining, smelting, building materials, roads, railways, water conservancy, chemical industry, and other industries. Click here to learn about the price of a jaw crusher!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Technical Parameters of Jaw Crusher:

| Model | Feeding Size | Discharging Opening Size | Capacity | Power | Weight | Overall Dimension |

| (mm) | (mm) | (t/h) | (kw) | (t) | (mm) | |

| YG250×400 | ≤210 | 20-60 | 5-21 | 15 | 2.8 | 1300*1090*1270 |

| YG400×600 | ≤340 | 40-100 | 16-64 | 30 | 7 | 1730*1730*1630 |

| YG500×750 | ≤425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

| YG600×900 | ≤500 | 65-160 | 50-160 | 55 | 17 | 2190*2206*2300 |

| YG750×1060 | ≤630 | 80-140 | 110-320 | 110 | 29 | 2660*2430*2800 |

| YG900×1200 | ≤750 | 95-165 | 220-380 | 132 | 52 | 3380*2870*3330 |

| YG1000x1200 | ≤850 | 195-265 | 315-500 | 160 | 55 | 3480*2876*3330 |

| YG1200×1500 | ≤1020 | 150-350 | 400-800 | 160-220 | 100.9 | 4200*3300*3500 |

| YG1500×1800 | ≤1200 | 220-350 | 500-1000 | 280-355 | 139 | 5160*3660*4248 |

| YGX150×750 | ≤120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

| YGX250×750 | ≤210 | 25-60 | 13-35 | 22 | 5.5 | 1380*1750*1540 |

| YGX250×1000 | ≤210 | 25-60 | 16-52 | 30 | 7 | 1560*1950*1390 |

| YGX250×1200 | ≤210 | 25-60 | 20-60 | 37 | 9.7 | 2140*1660*1500 |

| YGX300×1300 | ≤250 | 20-90 | 16-105 | 55 | 15.6 | 2720*1950*1600 |

| YGX500×1500 | ≤3250 | 25-120 | 50-160 | 90 | 20 | 2360*2660*2105 |

Working Principle of Jaw Crusher:

The motor drives the belts and the belt wheels, and makes the movable jaw up and down by the eccentric shaft. When the movable jaw descends, the angle between the fixed jaw and the movable jaw becomes smaller, and the materials can be crushed; when the movable jaw rises, the angle between the fixed jaw and the movable jaw becomes bigger; and the movable jaw plate leaves from the fixed jaw by the function of the tension rod and the spring. Then the crushed materials are discharged from the lower outlet of the crushing cavity.

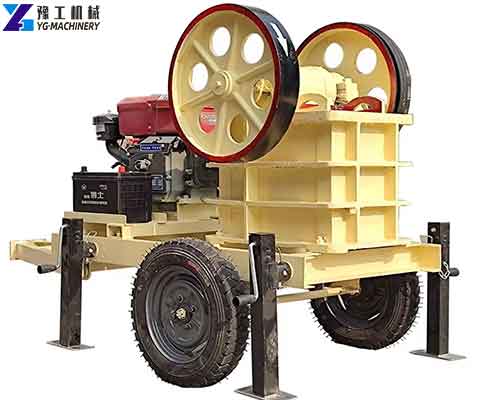

Mobile Jaw Crusher Performance Characteristics

- Large crushing ratio: It can quickly break large materials into smaller particles to meet different particle size requirements.

- Uniform product particle size: By adjusting parameters such as the outlet size of the crushing chamber and the speed of the crusher, the particle size distribution of the crushed materials can be controlled.

- Simple structure: The equipment consists of fewer parts and is easy to maintain and maintain.

- Reliable work: The use of sturdy and durable materials and structural design ensures that the equipment can still operate stably in harsh working environments.

- Low operating costs: The equipment has remarkable energy-saving effects. A single machine can save 15% to 30% of energy, and the system can save more than double the energy.

- Large adjustment range: The gasket-type discharge port adjustment device is reliable and convenient, and has a large adjustment range, which increases the flexibility of the equipment.

Portable Rock Crusher Application Scenarios:

Due to its high efficiency and reliability, jaw crushers are widely used in many industries. Mainly including:

- Mining industry: used to crush various mining resources, such as coal, iron ore, etc.

- Road construction and construction industry: used to crush raw materials for road construction and concrete for construction, etc.

- Water conservancy industry: provides sand and gravel aggregates for water conservancy projects.

- Metallurgy, cement, chemical, and other industries: used to crush materials with higher hardness, such as limestone, coal ash, etc.

- Environmental protection field: used to recycle and treat waste to reduce the impact on the environment.

Jaw Crusher Price – YG Machinery Manufacturer

Jaw crusher is an important crushing equipment, which plays an important role in many industries with its wide application fields and excellent performance characteristics. With the continuous advancement of technology and changes in market demand, jaw crushers will continue to develop in the direction of large-scale and intelligent, providing more efficient and reliable crushing solutions for the production and development of various industries. Of course, we also have hydraulic cone crushers, mobile crusher machines, stone crusher machines, excavator breaker machines, excavator pile breakers, excavator drill and splitting machines, excavator rock splitters, etc. Contact us for more machine details!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800