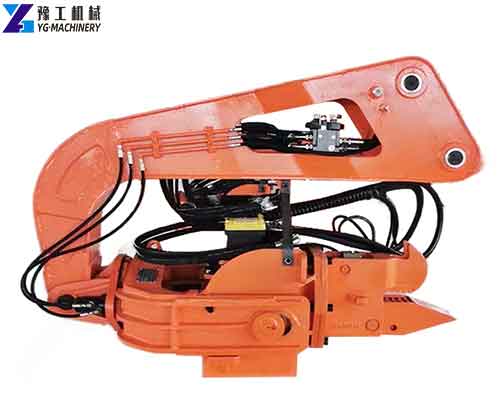

Excavator pile driver is mainly used for piling. The types of piles include pipe piles, steel sheet piles, steel pipe piles, precast concrete piles, wooden piles, and photovoltaic piles driven on water. They are particularly suitable for medium and short-pile projects such as municipal engineering, bridges, cofferdams, and building foundations.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Excavator Pile Driver Parameter:

| Model | YG150D | YG250D | YG350D | YG400D | YG450D |

| Eccentric moment(kg*m) | 3.2 | 5.1/5.7 | 7.1 | 9.2 | 11 |

| Speed(rpm) | 2600 | 2600 | 2600 | 2600 | 2600 |

| Excitation force(t) | 24 | 38/42 | 52 | 68 | 81 |

| Operating pressure of oil system(bar) | 200 | 300 | 320 | 330 | 330 |

| Flow demand for hydraulic oil system(lpm) | 100 | 163 | 220 | 260 | 300 |

| Weight(t) | 1.2 | 1.6 | 2.4 | 2.5 | 2.6 |

| Excavator(t) | 8-12 | 20-25 | 25-35 | 35-45 | 40-55 |

Product Features of Pile Driver for Mini Excavator:

- High efficiency: The speed of vibration pile sinking and extraction is generally 4-7 meters/minute, and the fastest is 12 meters/minute (in non-silty soil). The construction speed is much faster than other pile-driving machines, and 40%-100% higher than the efficiency of pneumatic hammers and diesel hammers.

- Wide range: Except for the inability to enter the rock, the high-frequency hydraulic pile driver is suitable for construction under almost any harsh geological conditions, and can easily penetrate the pebble layer, sand layer, and other geological conditions.

- Multiple functions: In addition to the construction of various types of bearing piles, the high-frequency hydraulic pile driver can also build thin-walled anti-seepage walls, deep compaction treatment, ground compaction treatment, and other special construction.

- Environmental protection: The vibration is small and the noise is low during work. The high-frequency hydraulic pile driver is equipped with a noise reduction power box, which can fully meet the environmental protection requirements when constructing in urban areas.

- Wide range of uses: suitable for driving piles of any shape and material, such as steel pipe piles and concrete pipe piles; suitable for any soil layer; can be used for piling, pulling piles, and underwater piling; can perform pile frame operations and suspension operations.

Applications of YG Excavator Pile Driver:

- Municipal construction: In municipal construction, steel pipe piles (casings) and other pile types used in supporting bored pile construction can be driven and pulled out by excavator pile drivers. This helps to improve the stability and safety of municipal infrastructure.

- Bridge construction: In bridge construction, to improve quality, shorten construction period, and reduce construction cost, excavator pile drivers are often used to drive and pull out pile types such as casings and steel sheet piles used in support and maintenance. The efficiency and accuracy of this equipment help to improve the overall quality of bridge projects.

- Building foundation: In building foundation treatment, excavator pile drivers also play an important role. It can drive various pile types (such as cement pipe piles, steel sheet piles, etc.) into the ground to provide a solid foundation support for buildings.

- Photovoltaic engineering: With the rapid development of the photovoltaic industry, the photovoltaic piling industry has an increasing demand for efficient and accurate piling equipment. With its high-frequency vibration characteristics, the excavator pile driver can quickly and accurately drive photovoltaic piles into the ground to meet the construction technical requirements of photovoltaic projects.

- Flood control projects: In flood control projects, a variety of pile types (such as steel sheet piles, cement pipe piles, square concrete precast piles, wooden piles, etc.) are needed to reinforce embankments and build flood control barriers. Excavator pile drivers can easily meet these needs and provide strong support for flood control projects.

Mini Excavator Pile Driver Working Principle

The working principle of the excavator pile driver is mainly to use high-frequency vibration to sink the pile into the soil. Specifically, it transmits the vertical vibration generated by the machine to the pile through a working system composed of a pile hammer, a jib, a clamp, and other equipment. This vibration causes the soil structure around the pile to change and reduce its strength, thereby liquefying the soil around the pile body and reducing the friction resistance between the pile side and the soil. Under the combined effect of the excavator’s downward pressure, the vibrating sinking and extraction hammer, and the pile body’s weight, the pile body is smoothly sunk into the soil. When pulling out the pile, the pile is pulled out by the excavator’s upward lifting force and vibration.

Excavator Pile Driver Manufacturer – YG Machinery

As one of the important equipment in construction projects, excavator pile drivers have broad market prospects and development space. With the continuous advancement of technology and changes in market demand, the pile driver market will show a more diversified, intelligent, and environmentally friendly development trend. As a brand leader in the construction machinery field for more than 20 years, YG Machinery has been creating easier-to-operate and more cost-effective equipment by combining customer experience feedback with the most advanced technology. In addition, we also have excavator rock splitters, excavator drill and splitting machines, excavator hydraulic shears, excavator drum cutters, excavator crusher buckets, excavator pile breakers, excavator rock saws, excavator hydraulic breakers, mobile crusher machines, etc. Contact us for more details soon!【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800